Overview of 95 Tungsten Nickel Iron Round cake Powder Metallurgy High Density Tungsten Alloy 90 Tungsten Nickel Copper Target

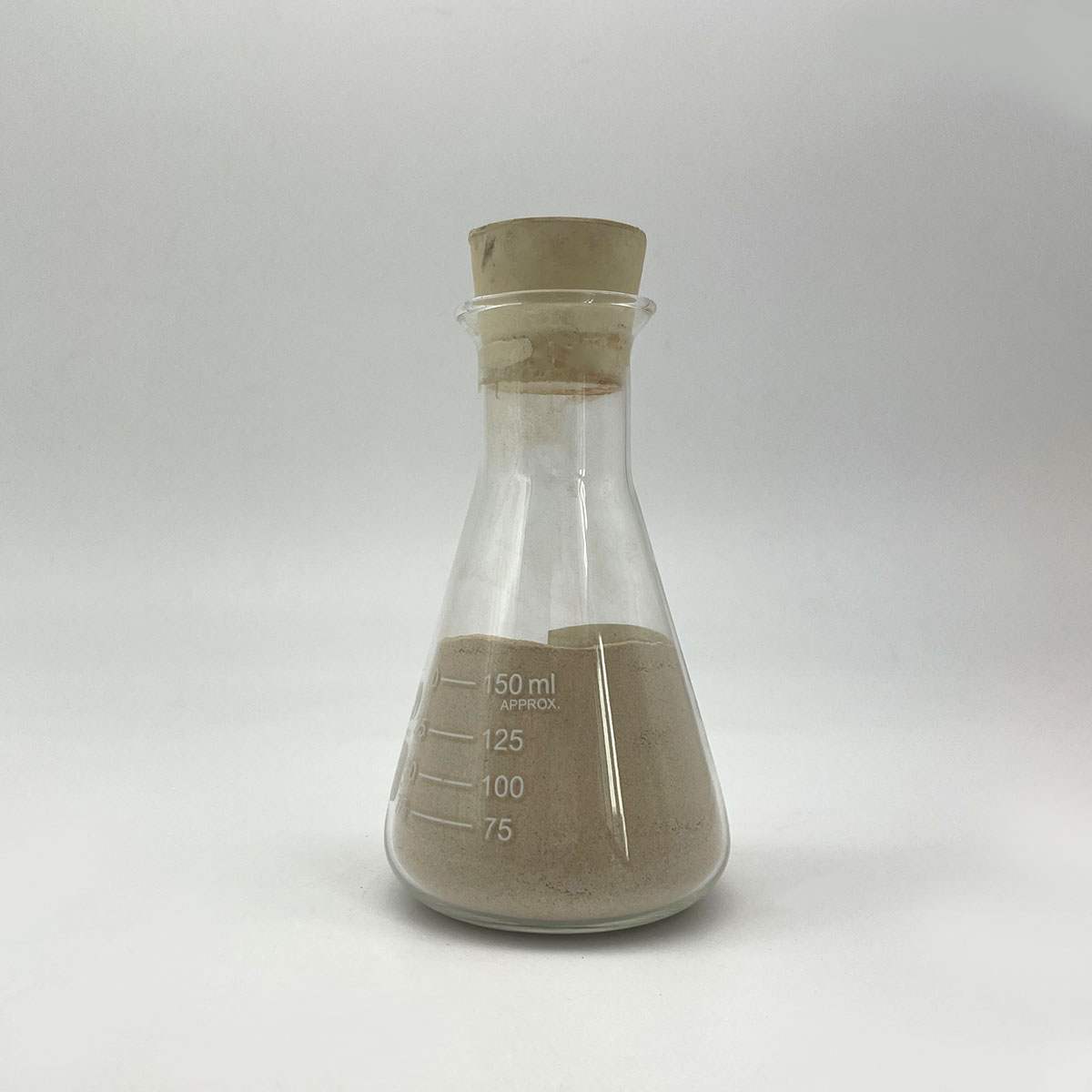

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of 95 Tungsten Nickel Iron Round cake Powder Metallurgy High Density Tungsten Alloy 90 Tungsten Nickel Copper Target

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(95 Tungsten Nickel Iron Round cake Powder Metallurgy High Density Tungsten Alloy 90 Tungsten Nickel Copper Target)

Parameters of 95 Tungsten Nickel Iron Round cake Powder Metallurgy High Density Tungsten Alloy 90 Tungsten Nickel Copper Target

Title: Advanced Tungsten-Nickel-Iron Round Cake Powders for Precision Metallurgy: A High-Density Tungsten Alloy Target

Introduction:

In the field of advanced materials and cutting-edge technology, tungsten alloys hold a prominent position due to their exceptional properties, such as high density, strength, and thermal stability. One such compound, 95% tungsten with 5% nickel and iron (nickel-iron tungsten alloy), is a popular choice in powder metallurgy applications. This particular round cake form, often utilized in target manufacturing, showcases the versatility of this material.

Composition and Characteristics:

The 95Tungsten Nickel Iron Round Cake Powder is a composite material consisting of 95% tungsten, which is known for its unparalleled density (19.3 g/cm³) and high melting point (3422°C). Nickel (5%) acts as a strengthening agent, enhancing the alloy’s mechanical properties, while iron (also 5%) provides some ductility and improves machinability. The powder metallurgy process allows for the creation of a homogeneous structure with fine grain sizes, resulting in superior wear resistance and dimensional accuracy.

Properties:

This high-density tungsten alloy offers excellent thermal conductivity, making it ideal for applications requiring heat transfer or radiation shielding. Its high melting point ensures durability under extreme conditions, such as in aerospace, defense, and energy industries where components must withstand high temperatures. The round cake form also facilitates handling and compacting during the fabrication process.

Applications:

The 90Tungsten Nickel Copper Target Parameter finds extensive use in various sectors. In the electronics industry, it serves as a critical component in semiconductor manufacturing, where precise targets are used in electron beam lithography for etching microchips. In the field of medical physics, these tungsten alloys are employed for radiation therapy, where they are used in high-energy particle accelerators to create focused beams.

In the aerospace and defense industries, tungsten alloys like this one are employed in the production of high-performance targets for missile guidance systems, hypersonic vehicles, and armor-penetrating projectiles. Their high density and strength make them ideal for lightweight yet robust components that can withstand immense forces.

Powder Metallurgy Process:

The powder metallurgy technique employed in creating the 95Tungsten Nickel Iron Round Cake Powder involves the sintering of tungsten, nickel, and iron powders under controlled atmospheres. This process ensures minimal porosity and uniform distribution of the elements, resulting in a superior final product with enhanced mechanical properties compared to conventional casting methods.

Conclusion:

In summary, the 95Tungsten Nickel Iron Round Cake Powder Metallurgy represents a high-performance material for demanding applications. Its unique combination of high density, strength, and thermal stability, along with the precision achievable through powder metallurgy, makes it an indispensable target material in various industries, from electronics to defense. As technology continues to advance, the potential uses and benefits of this tungsten alloy will only continue to grow.

(95 Tungsten Nickel Iron Round cake Powder Metallurgy High Density Tungsten Alloy 90 Tungsten Nickel Copper Target)

FAQs of 95 Tungsten Nickel Iron Round cake Powder Metallurgy High Density Tungsten Alloy 90 Tungsten Nickel Copper Target

Inquiry us