Overview of 99.9999% 5n grade high purity tungsten powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of 99.9999% 5n grade high purity tungsten powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

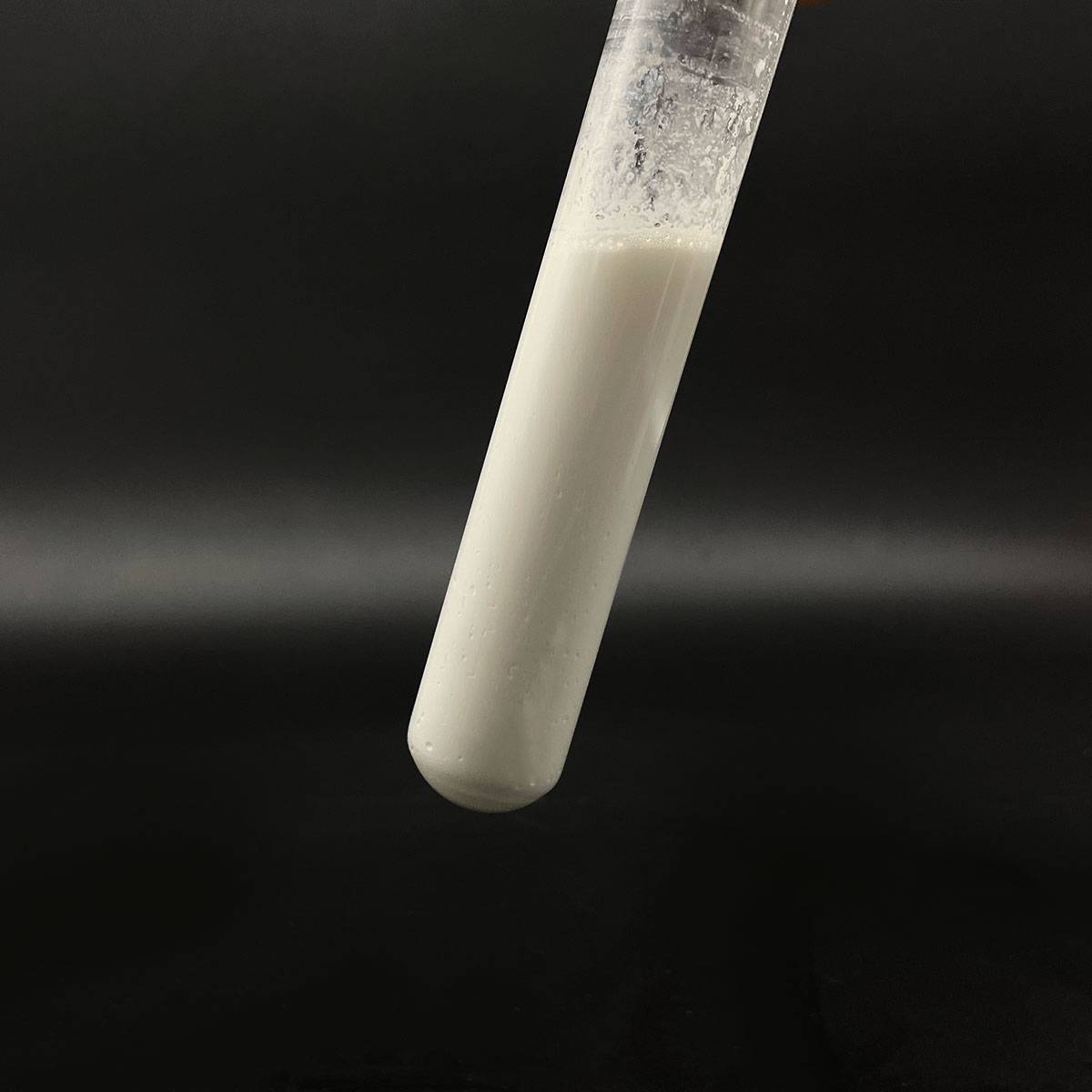

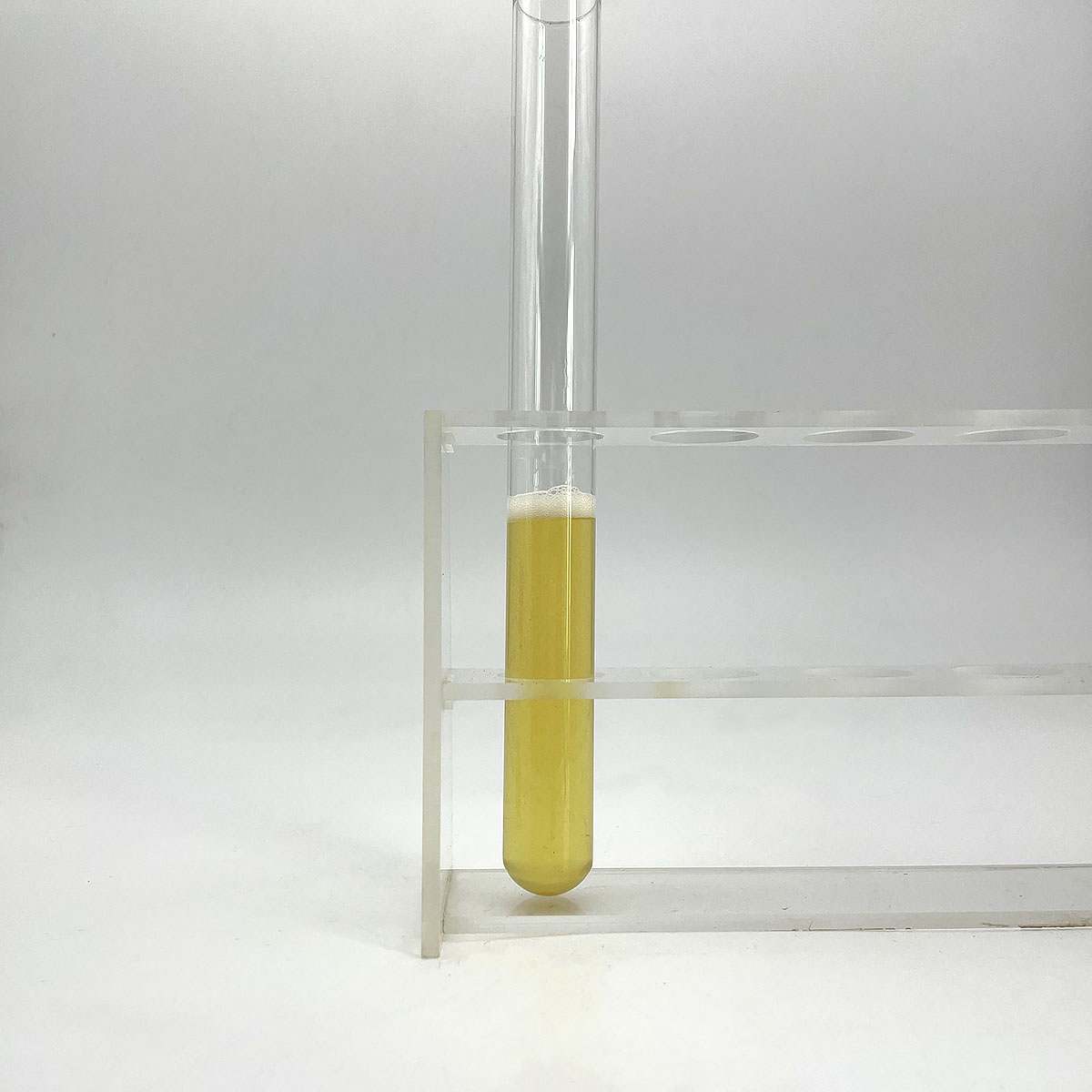

(99.9999% 5n grade high purity tungsten powder)

Parameters of 99.9999% 5n grade high purity tungsten powder

High Purity Tungsten Powder: A Crucial Ingredient in Advanced Technologies

Tungsten, with the chemical symbol W, is a remarkable metal that boasts an atomic number 74 on the periodic table. It is renowned for its exceptional strength, density, and resistance to extreme temperatures, making it a preferred material in various cutting-edge applications. When we refer to “99.9999% 5N grade high purity tungsten powder,” we are discussing a product of unparalleled quality that is at the forefront of modern technology.

The term “5N” in this context refers to the standard of particle purity. The “N” stands for “normal” or “number,” and a higher number indicates a higher level of purity. A 5N grade tungsten powder means that it contains less than 1 part impurity per million parts of tungsten. This level of purity ensures that the material’s properties remain consistent and undisturbed by contaminants, making it ideal for precision work and demanding applications.

The high purity tungsten powder is produced through a meticulous refining process. It begins with the extraction of tungsten from its ores, typically through a combination of roasting, smelting, and chemical purification steps. The purification process involves multiple stages of refining, including leaching, precipitation, and electrolysis, to eliminate impurities such as iron, copper, and other metals. Each step is carefully controlled to achieve the desired 5N standard.

This ultra-pure tungsten powder has a number of unique characteristics. It has a melting point of around 3,422°C (6,202°F), making it one of the highest-melting-point materials available. Its density, approximately 19.25 g/cm³, gives it outstanding strength-to-weight ratio, which is crucial in aerospace, defense, and energy industries. Additionally, tungsten possesses excellent thermal conductivity, allowing it to dissipate heat effectively, which is vital in high-temperature applications like light bulbs and electronic components.

In the field of electronics, tungsten finds use in the manufacturing of filaments for incandescent bulbs due to its ability to emit intense light without degrading quickly. It is also employed in X-ray tubes, where its high melting point enables it to withstand the intense radiation. In the semiconductor industry, tungsten is used in advanced lithography processes, where its fine powder form allows for precise deposition onto substrates.

Furthermore, tungsten is a key component in the production of cutting tools, wear-resistant coatings, and even nuclear reactors, where its stability under high temperatures and resistance to neutron bombardment make it indispensable. The 99.9999% 5N grade tungsten powder ensures that these applications benefit from superior performance and longevity.

In conclusion, the 99.9999% 5N grade high purity tungsten powder is a testament to human ingenuity and technological advancement. Its exceptional purity, combined with its inherent properties, makes it an essential material in a wide range of industries, from traditional lighting to cutting-edge scientific research. As technology continues to evolve, the demand for such high-quality tungsten powders will only grow, ensuring its enduring role in shaping the future.

(99.9999% 5n grade high purity tungsten powder)

FAQs of 99.9999% 5n grade high purity tungsten powder

Inquiry us