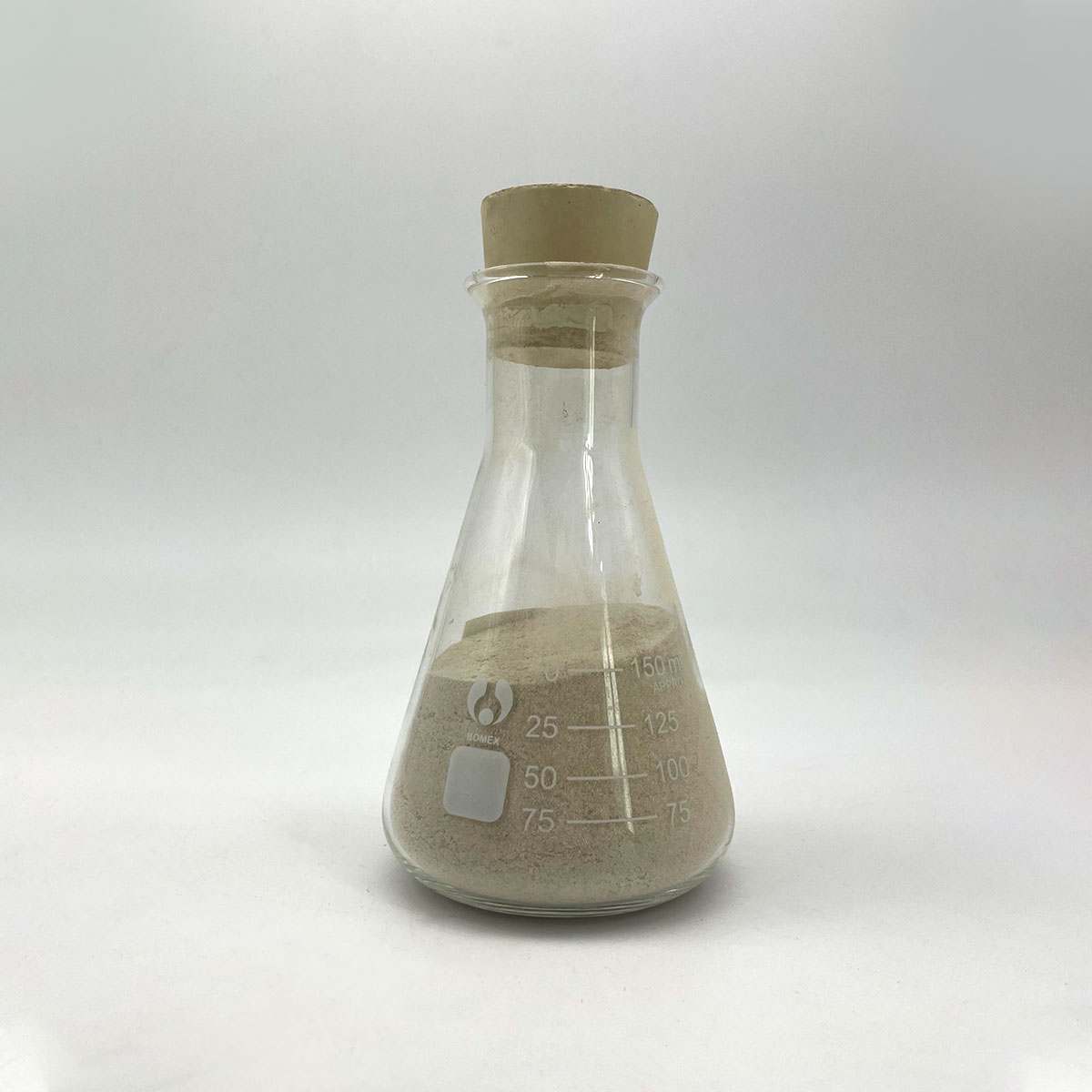

Overview of High quality crushed scrap tungsten carbide grits granule particle grain powder sand

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of High quality crushed scrap tungsten carbide grits granule particle grain powder sand

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(High quality crushed scrap tungsten carbide grits granule particle grain powder sand)

Parameters of High quality crushed scrap tungsten carbide grits granule particle grain powder sand

Title: High-Quality Crushed Scrap Tungsten Carbide Grits: A Comprehensive Overview

Introduction:

Tungsten carbide, a renowned superalloy, is a combination of tungsten and carbon in a metallic state. It boasts exceptional hardness, wear resistance, and thermal stability, making it indispensable in various industrial applications, including cutting tools, wear-resistant coatings, and abrasive materials. This article delves into the high-quality crushed scrap tungsten carbide grits, their properties, and their role as a premium abrasive component.

Properties of Tungsten Carbide:

1. Composition: Tungsten carbide is primarily composed of tungsten (95% W) and carbon (5%), with trace amounts of cobalt and other elements to enhance its mechanical properties. The hardness of pure tungsten carbide can reach up to 2,800 HV, making it one of the hardest materials available.

2. Hardness and Durability: The crushed scrap tungsten carbide grits maintain this inherent hardness even after being reduced to smaller particles. These grits exhibit excellent resistance to wear, enabling them to withstand rigorous abrasive processes without losing their sharpness.

3. Thermal Stability: Tungsten carbide has a low coefficient of thermal expansion, ensuring that the material’s properties remain consistent across a wide temperature range. This stability is crucial for applications where temperature fluctuations are prevalent.

4. Chemical Resistance: Resistant to acids, alkalis, and most chemicals, tungsten carbide grits can withstand harsh environments without degrading.

Crushing Process:

The high-quality tungsten carbide starts as a scrap material from worn-out cutting tools or other applications. To produce the crushed grits, the scrap undergoes a controlled crushing process, which includes sorting, sizing, and purification. This process ensures that the final product consists of uniform, high-purity particles with a consistent size distribution.

Particle Size and Grading:

Crushed tungsten carbide grits are available in a variety of particle sizes, ranging from sub-micron to coarse grits suitable for grinding, lapping, or polishing. The grading system typically follows the ANSI/SAE standard, with grit sizes labeled as P120, P240, P400, etc., corresponding to finer to coarser abrasive particles.

Applications:

1. Cutting Tools: As an abrasive, tungsten carbide grits are used in the manufacturing of high-performance cutting tools, such as end mills, drills, and inserts, for precision machining of metals.

2. Wear-resistant Coatings: The grits are employed in wear-resistant coatings on machinery components to prolong their lifespan and improve efficiency.

3. Abrasive Media: In sandblasting, lapping, and polishing processes, tungsten carbide grits offer exceptional surface finish and durability.

4. Industrial Polishing: They are utilized in the polishing of jewelry, glass, and other delicate surfaces due to their gentle yet effective abrasive action.

Conclusion:

High-quality crushed scrap tungsten carbide grits are a vital component in modern industry, thanks to their unique properties and versatile applications. Their exceptional hardness, thermal stability, and chemical resistance make them a preferred choice for demanding abrasive tasks. By understanding their composition, crushing process, and grading, users can select the most appropriate grits for their specific requirements, ensuring optimal performance and longevity.

(High quality crushed scrap tungsten carbide grits granule particle grain powder sand)

FAQs of High quality crushed scrap tungsten carbide grits granule particle grain powder sand

Inquiry us