Overview of high–quality rare metal powders for tungsten carbide search buyers who demand large

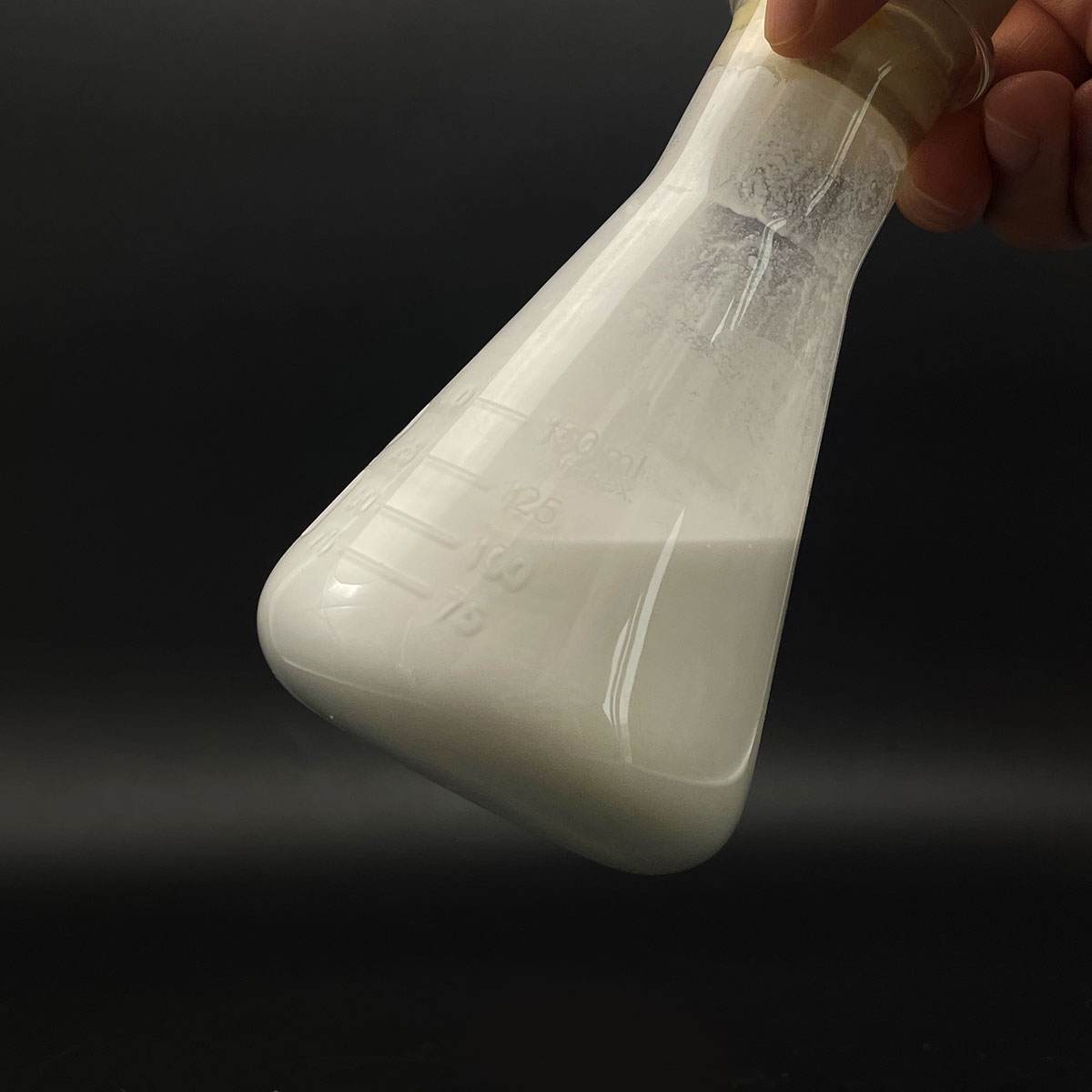

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of high–quality rare metal powders for tungsten carbide search buyers who demand large

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(high–quality rare metal powders for tungsten carbide search buyers who demand large)

Parameters of high–quality rare metal powders for tungsten carbide search buyers who demand large

Title: High-Quality Rare Metal Powders for Tungsten Carbide: A Premium Choice for Demanding Industries

In today’s highly competitive manufacturing landscape, the pursuit of excellence and efficiency has led to an increased demand for high-quality rare metal powders, particularly in the production of tungsten carbide. Tungsten carbide, known for its exceptional hardness, wear resistance, and thermal stability, is a material of choice for various applications, ranging from cutting tools, bearings, to wear-resistant coatings. As a sought-after component, the quality of these powders plays a pivotal role in ensuring the longevity and performance of end products.

The process of creating tungsten carbide begins with the refinement of rare earth metals like tungsten and carbon, which are combined in specific ratios to form the desired powder. The purity and particle size distribution of these powders are critical parameters that define their final characteristics. High-quality rare metal powders for tungsten carbide must possess:

1. Purity: A minimum purity level is essential to maintain the desired properties of the final product. Impurities can compromise strength, wear resistance, and overall performance. Manufacturers seeking premium powders should look for suppliers that adhere to strict quality control standards, ensuring minimal contamination.

2. Particle Size Distribution: A consistent and narrow particle size distribution is crucial for achieving uniform material properties and efficient processing. This ensures that the tungsten carbide will have a predictable microstructure, leading to better mechanical properties and surface finish in the final components.

3. Homogeneity: The uniformity of the powder composition is vital for obtaining consistent material properties across the batch. High-quality powders exhibit a homogeneous mixture of tungsten and carbon, minimizing variations in hardness and wear resistance.

4. Flowability: Good flowability is necessary for easy handling during the sintering process, which involves compacting the powder into a solid piece. Powders with low agglomeration and high flowability ensure a more efficient and cost-effective manufacturing process.

5. Sinterability: The ability of the powder to form a dense, strong, and well-adhered structure when subjected to heat and pressure is another critical parameter. High-quality rare metal powders demonstrate excellent sinterability, resulting in a dense tungsten carbide product with fewer defects.

6. Environmental Compatibility: As sustainability becomes a growing concern, suppliers of high-quality rare metal powders should provide eco-friendly options, such as those produced using sustainable mining practices and low-emission processes.

Potential buyers, whether they are manufacturers, research institutions, or specialized equipment providers, should prioritize partnering with reputable suppliers who can consistently deliver high-quality rare metal powders for tungsten carbide. These suppliers should be able to provide detailed technical support, certifications, and reliable supply chain management to meet the evolving demands of the market.

In conclusion, the quest for high-quality rare metal powders for tungsten carbide is not just about meeting basic requirements; it’s about unlocking the full potential of this remarkable material. By focusing on purity, particle size distribution, homogeneity, flowability, sinterability, and environmental compatibility, buyers can ensure that their investments in tungsten carbide-based products yield superior performance and long-term reliability. As the demand for advanced materials continues to rise, the importance of sourcing high-quality powders will only become more pronounced.

(high–quality rare metal powders for tungsten carbide search buyers who demand large)

FAQs of high–quality rare metal powders for tungsten carbide search buyers who demand large

Inquiry us