Overview of Tungsten particles

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Tungsten particles

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

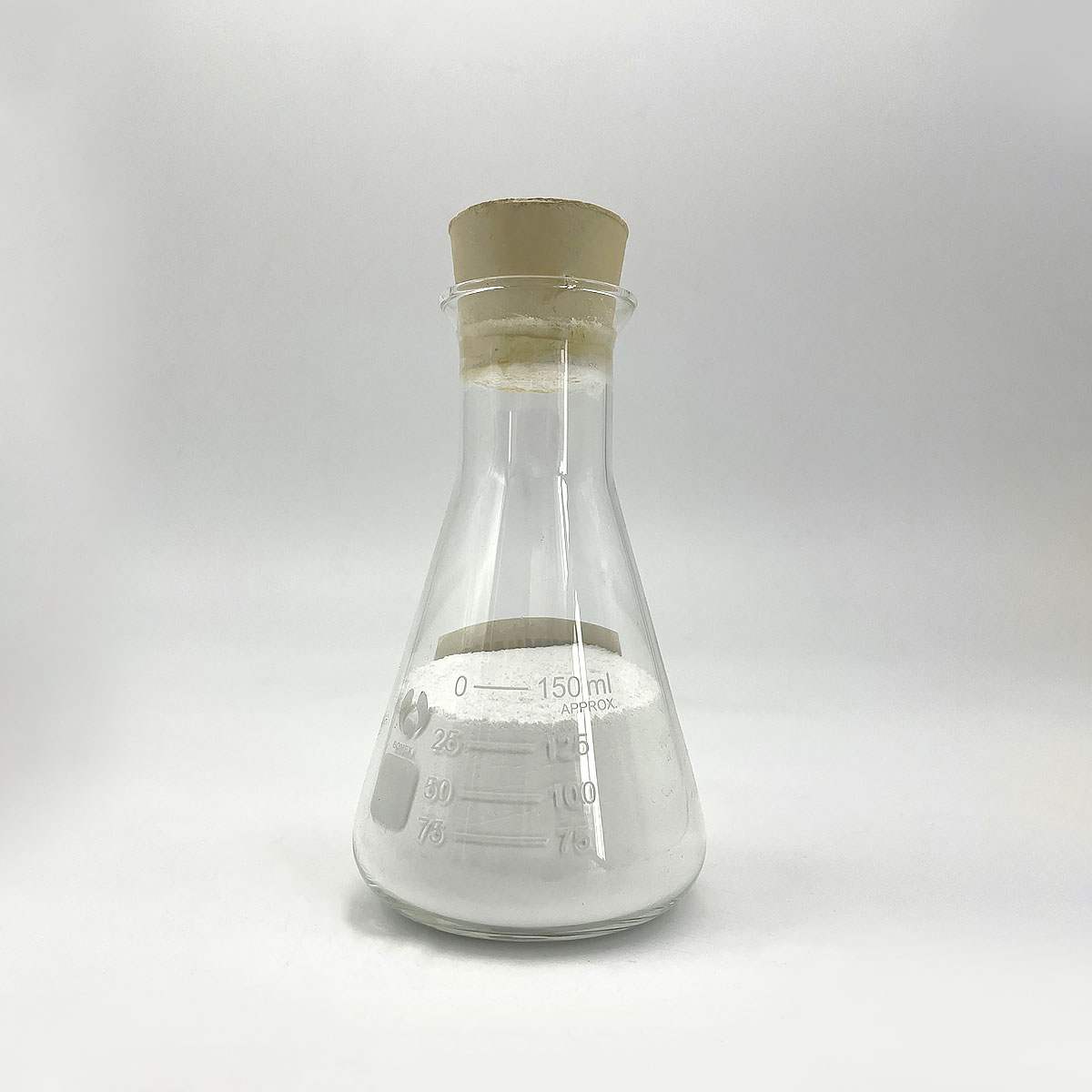

(Tungsten particles)

Parameters of Tungsten particles

Tungsten particles, also known as tungsten nano- or microparticles, are elemental particles of the chemical element tungsten (W) that exist in various sizes ranging from nanometers to micrometers. These unique particles possess distinct physical and chemical properties due to their small size, which make them highly versatile in various applications across science, engineering, and technology.

Tungsten is a dense, hard, and corrosion-resistant metal with an atomic number of 74 and an atomic weight of approximately 183.8 grams per mole. It has a melting point of around 3,422 degrees Celsius (6,212 degrees Fahrenheit), making it one of the highest-melting-point elements on Earth. As particles, tungsten maintains these exceptional properties at the nanoscale, making it suitable for high-temperature and high-stress environments.

The surface area-to-volume ratio of tungsten particles increases significantly when they become smaller, leading to enhanced reactivity and catalytic properties. Nanotungsten particles can act as efficient catalysts in chemical reactions due to their large surface area, allowing for improved reaction rates and selectivity. This feature has been exploited in industries like automotive exhaust systems, where tungsten-based catalysts help reduce harmful emissions.

In the field of electronics, tungsten particles are used in advanced materials like tungsten carbide (WC) and tungsten silicide (WSi), which are employed in cutting tools, wear-resistant coatings, and even in semiconductor manufacturing. The high thermal conductivity and stability of tungsten particles make them ideal for heat sink applications, ensuring efficient heat dissipation in electronic devices.

In the aerospace industry, tungsten particles find use in ablative thermal protection systems (ATPS), where they provide lightweight yet strong material that can withstand extreme temperatures during re-entry into the Earth’s atmosphere. The particles’ ability to withstand high temperatures without melting or vaporizing is crucial for protecting spacecraft.

Moreover, tungsten particles have applications in medicine, particularly in radiation therapy. Due to their high density, they can effectively deliver targeted radiation doses to cancerous tumors while minimizing damage to surrounding healthy tissue. This makes them a component of particle accelerators and ion beams used in radiation oncology.

Lastly, tungsten particles play a role in additive manufacturing or 3D printing, where they can be used as feedstock for creating parts with exceptional strength and durability. Fine tungsten particles can be fused together layer by layer to produce components with high-temperature resistance and excellent mechanical properties.

In conclusion, tungsten particles, regardless of their size, exhibit unique properties that make them valuable in various sectors. From catalysis and electronics to aerospace, medicine, and manufacturing, tungsten particles are continuously being harnessed for innovative solutions that push the boundaries of technology and improve our daily lives. Their versatility and inherent strength make tungsten an essential material in the modern world.

(Tungsten particles)

FAQs of Tungsten particles

Inquiry us