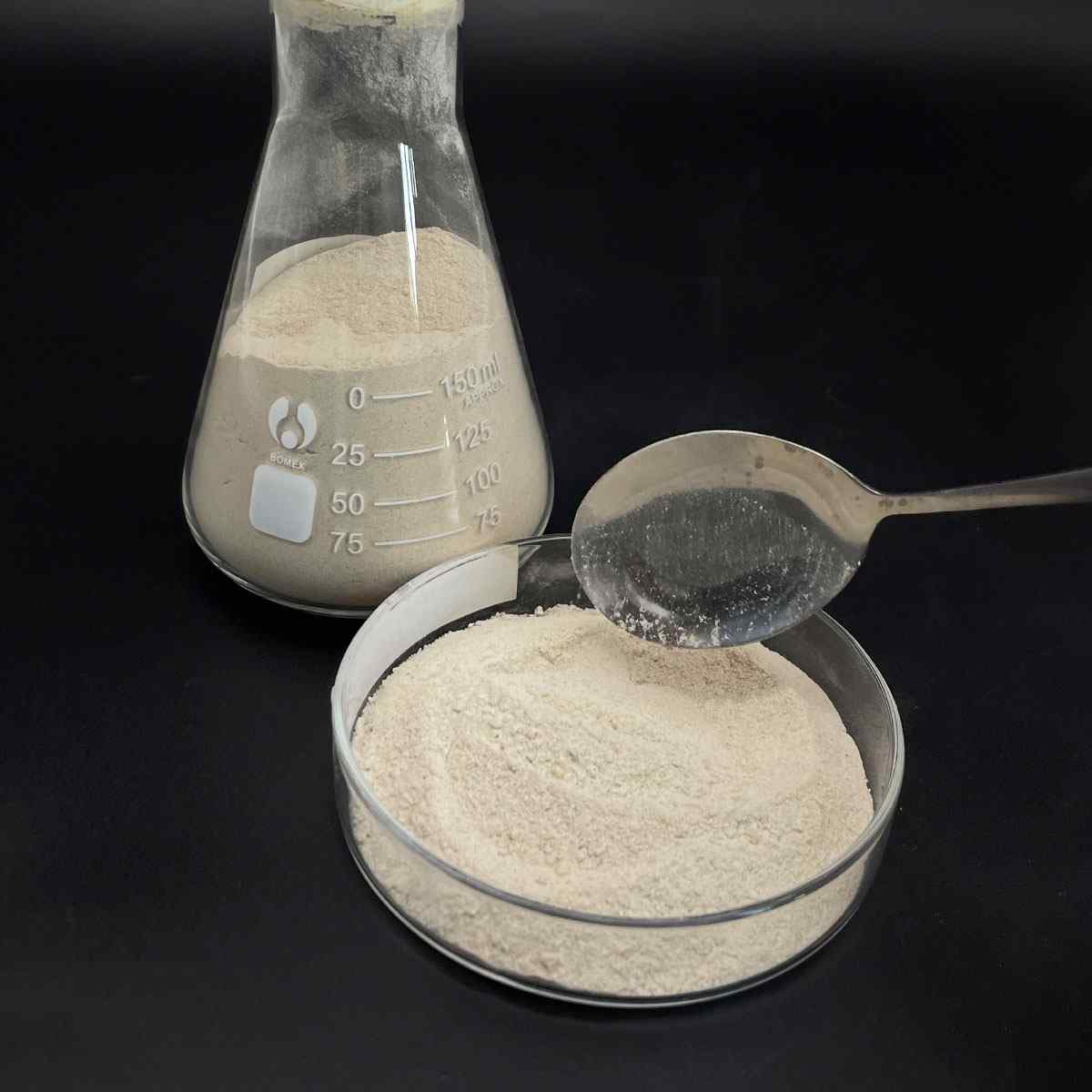

Overview of High Purity MoS2 low Molybdenum Disulfide Mos2 Molybdenum Disulfide Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of High Purity MoS2 low Molybdenum Disulfide Mos2 Molybdenum Disulfide Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(High Purity MoS2 low Molybdenum Disulfide Mos2 Molybdenum Disulfide Powder)

Parameters of High Purity MoS2 low Molybdenum Disulfide Mos2 Molybdenum Disulfide Powder

Molybdenum disulfide (MoS2), also known as molygraphite or mos2 powder, is a versatile inorganic compound with a chemical formula of MoS2. It is composed of molybdenum (Mo) atoms sandwiched between layers of sulfur (S) atoms, forming a unique two-dimensional crystal structure that has garnered significant attention in recent years due to its extraordinary properties and potential applications.

High purity MoS2 typically refers to samples with a minimum impurity level, ensuring the material’s quality and performance. The purity is often measured as the percentage of MoS2 in the total mass, with higher purity grades indicating fewer contaminants such as metal oxides, carbon, or other impurities. This purity is critical for applications where high efficiency, reliability, and stability are essential, such as in electronics, lubricants, and energy storage devices.

The crystal structure of MoS2 is composed of hexagonal planes, which gives it a layered, van der Waals nature. This layered structure allows for easy exfoliation, turning the material into single- or few-layer forms, known as molybdenum disulfide nanosheets or graphene-like materials. These nanostructures exhibit exceptional electronic, thermal, and mechanical properties, making them attractive for various applications.

One of the most notable features of MoS2 is its semiconducting behavior, with a bandgap that can be tuned depending on the number of layers. Monolayer MoS2 is a direct bandgap semiconductor, which means it can efficiently absorb light and convert it into electricity, making it a promising candidate for optoelectronic devices like photodetectors and solar cells.

In addition to its electronic properties, MoS2 demonstrates excellent lubricity due to the weak Van der Waals forces between its layers. As a result, it is widely used in high-performance lubricants, bearings, and coatings for reducing friction and wear. The material’s thermal conductivity is also noteworthy, with MoS2 being an effective heat spreader in electronic components, improving overall device performance.

Molybdenum disulfide powder is synthesized through various methods, including chemical vapor deposition (CVD), hydrothermal synthesis, and mechanical exfoliation from bulk crystals. Each process influences the particle size, morphology, and surface area, which can impact the final properties of the material. High purity MoS2 powders are typically characterized by their particle size distribution, which can range from submicron to nanometer scales, depending on the application requirements.

In conclusion, high purity MoS2 is a fascinating material with a wide range of potential applications due to its unique properties. Its layered structure, tunable bandgap, exceptional lubrication, and thermal conductivity make it an important component in areas such as electronics, energy storage, and advanced materials science. The pursuit of even higher purity and the development of new synthesis techniques continue to drive research and innovation in this field.

(High Purity MoS2 low Molybdenum Disulfide Mos2 Molybdenum Disulfide Powder)

FAQs of High Purity MoS2 low Molybdenum Disulfide Mos2 Molybdenum Disulfide Powder

Inquiry us