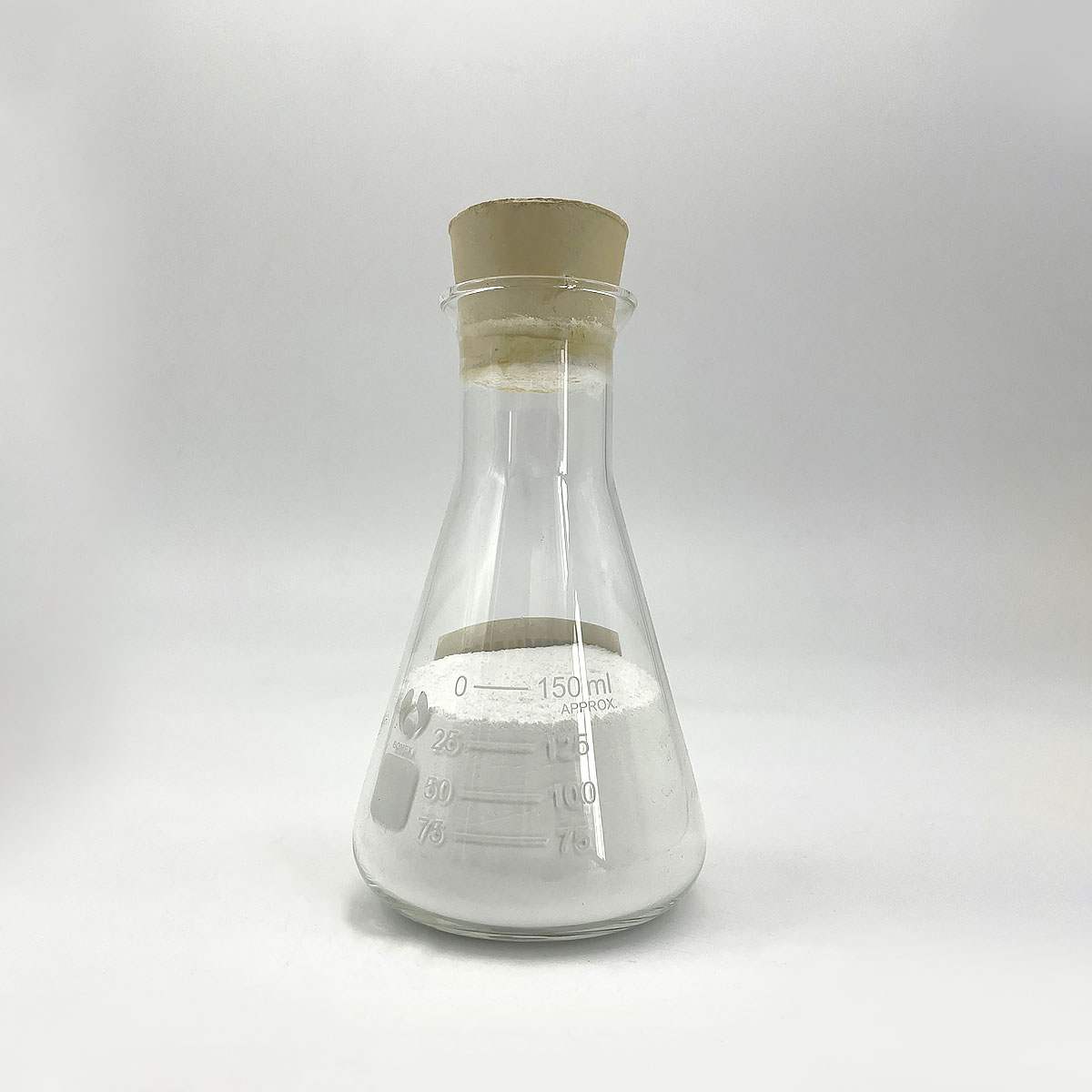

Overview of Molybdic Acid85% Extra Pure Molybdic acid is the hydrated form of molybdenum trioxide is also knownas molybdenum hydroxide oxide

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Molybdic Acid85% Extra Pure Molybdic acid is the hydrated form of molybdenum trioxide is also knownas molybdenum hydroxide oxide

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Molybdic Acid85% Extra Pure Molybdic acid is the hydrated form of molybdenum trioxide is also knownas molybdenum hydroxide oxide)

Parameters of Molybdic Acid85% Extra Pure Molybdic acid is the hydrated form of molybdenum trioxide is also knownas molybdenum hydroxide oxide

Molybdic acid, specifically 85% extra pure, is a chemical compound that plays a significant role in various industrial and scientific applications. It is derived from the element molybdenum, which is a transition metal found on the periodic table, and its hydrate form is often referred to as molybdenum hydroxide oxide or molybdate. This particular grade of molybdic acid is highly purified, ensuring a high concentration of active molybdenum ions and minimal impurities.

The chemical formula for molybdic acid is typically represented as H2MoO4, indicating that it consists of two moles of hydrogen (H2) bonded to one mole of molybdenum dioxide (MoO3). The extra purity level of 85% means that it contains approximately 85 parts by weight of molybdenum trioxide, with the remaining 15% being water or other trace elements.

Molybdic acid finds its applications in diverse industries due to its unique properties. In the steel industry, it acts as a hardening agent, enhancing the wear resistance and toughness of steel alloys, particularly in high-temperature environments. This makes it crucial for components used in automotive, aerospace, and power generation sectors.

In the chemical industry, molybdic acid is employed in catalysts, where it plays a vital role in processes such as hydrodesulfurization, which removes sulfur compounds from crude oil, improving the quality of refined products. It is also used in the production of molybdenum compounds like molybdenum disulfide, a lubricant with exceptional friction-reducing properties.

In environmental applications, molybdic acid is used as a component in wastewater treatment processes, where it helps in the removal of heavy metals and promotes the formation of stable precipitates that can be easily separated and treated. Its ability to selectively bind certain contaminants makes it an essential tool in water purification.

Moreover, molybdic acid has applications in the field of electronics, where it is used in the fabrication of semiconductors due to its ability to improve the performance of electronic devices. It can enhance the stability and efficiency of catalysts in fuel cells, contributing to cleaner energy production.

The 85% extra pure molybdic acid is usually stored in a concentrated solution, requiring proper handling and safety measures due to its corrosive nature. It is essential to maintain appropriate storage conditions, including temperature control and sealing, to prevent evaporation and contamination.

In conclusion, molybdic acid, especially the 85% extra pure variety, is a versatile chemical compound with a wide range of uses across various industries. Its high purity and unique properties make it a valuable material in applications that demand enhanced performance, durability, and selectivity. As research and technology continue to evolve, the potential applications for molybdic acid are expected to expand even further.

(Molybdic Acid85% Extra Pure Molybdic acid is the hydrated form of molybdenum trioxide is also knownas molybdenum hydroxide oxide)

FAQs of Molybdic Acid85% Extra Pure Molybdic acid is the hydrated form of molybdenum trioxide is also knownas molybdenum hydroxide oxide

Inquiry us