Overview of high quality monolayer molybdenum disulfide powder/mos2 powder for

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of high quality monolayer molybdenum disulfide powder/mos2 powder for

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

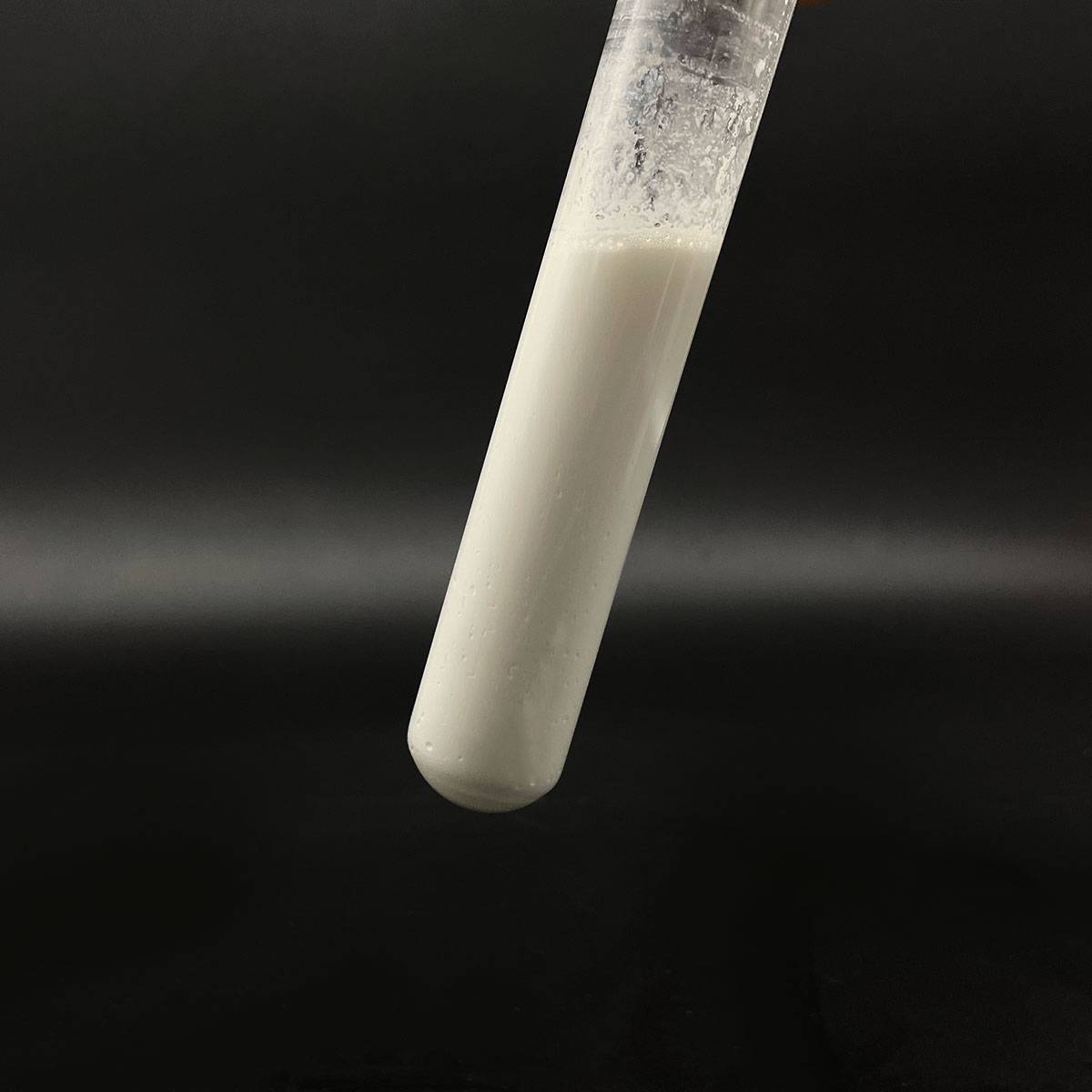

(high quality monolayer molybdenum disulfide powder/mos2 powder for )

Parameters of high quality monolayer molybdenum disulfide powder/mos2 powder for

Molybdenum disulfide (MoS2), also known as MoS2 powder, is a two-dimensional material with extraordinary properties that have garnered significant attention in the scientific community and industry alike. This high-quality monolayer material, with its atomic-scale thickness, exhibits exceptional characteristics that make it a promising candidate for various applications, from electronics to energy storage and even biomedical fields.

Monolayer MoS2, often referred to as a single-layer MoS2, consists of a single layer of molybdenum atoms sandwiched between sulfur atoms, forming a hexagonal lattice structure. It is part of the transition metal dichalcogenide family, which includes other layered materials like graphene and tungsten diselenide. The unique crystal structure gives rise to its remarkable electronic, mechanical, and thermal properties.

One of the most striking features of MoS2 is its direct bandgap, which allows for efficient light absorption and conversion. This makes it an attractive material for optoelectronic devices such as photodetectors, solar cells, and light-emitting diodes (LEDs). Monolayer MoS2’s high carrier mobility, on the order of tens to hundreds of centimeters squared per volt-second, enables faster and more efficient charge transport, ideal for next-generation electronic devices.

In terms of mechanical strength, MoS2 is known for its exceptional flexibility and robustness, despite its lightweight. The single-layer form demonstrates an impressive tensile strength of around 130 gigapascals, making it a potential material for flexible electronics and wearable technology. Additionally, its inherent self-healing capabilities can help maintain its integrity under stress.

MoS2’s thermal stability is another key parameter, with a high melting point of approximately 1,160°C, which is advantageous for high-temperature applications like heat dissipation and thermal management. Its thermal conductivity is also relatively high, contributing to efficient heat transfer.

From a chemical perspective, MoS2 is resistant to corrosion and has good compatibility with various substrates, making it suitable for integration into diverse systems. However, it is essential to note that the quality of the monolayer MoS2 powder significantly impacts its performance. High-quality MoS2 powder should exhibit low impurity levels, uniform particle size distribution, and well-defined crystal structure, ensuring optimal performance in practical applications.

The synthesis of high-quality monolayer MoS2 powder typically involves techniques like chemical vapor deposition (CVD), mechanical exfoliation, or chemical reduction methods. These processes require careful control and optimization to yield defect-free, large-area, and highly crystalline flakes or powders.

In conclusion, high-quality monolayer molybdenum disulfide powder is a sought-after material due to its unique combination of electronic, mechanical, and thermal properties. As research continues to uncover new possibilities, this material holds immense potential in various industries, from advanced electronics to energy storage and even nanomedicine. The pursuit of purity, consistency, and scalability in the production of MoS2 powder is crucial for unlocking its full potential and driving innovation forward.

(high quality monolayer molybdenum disulfide powder/mos2 powder for )

FAQs of high quality monolayer molybdenum disulfide powder/mos2 powder for

Inquiry us