Overview of Hot molybdenum trioxide 99.5%Min MoO3

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Hot molybdenum trioxide 99.5%Min MoO3

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

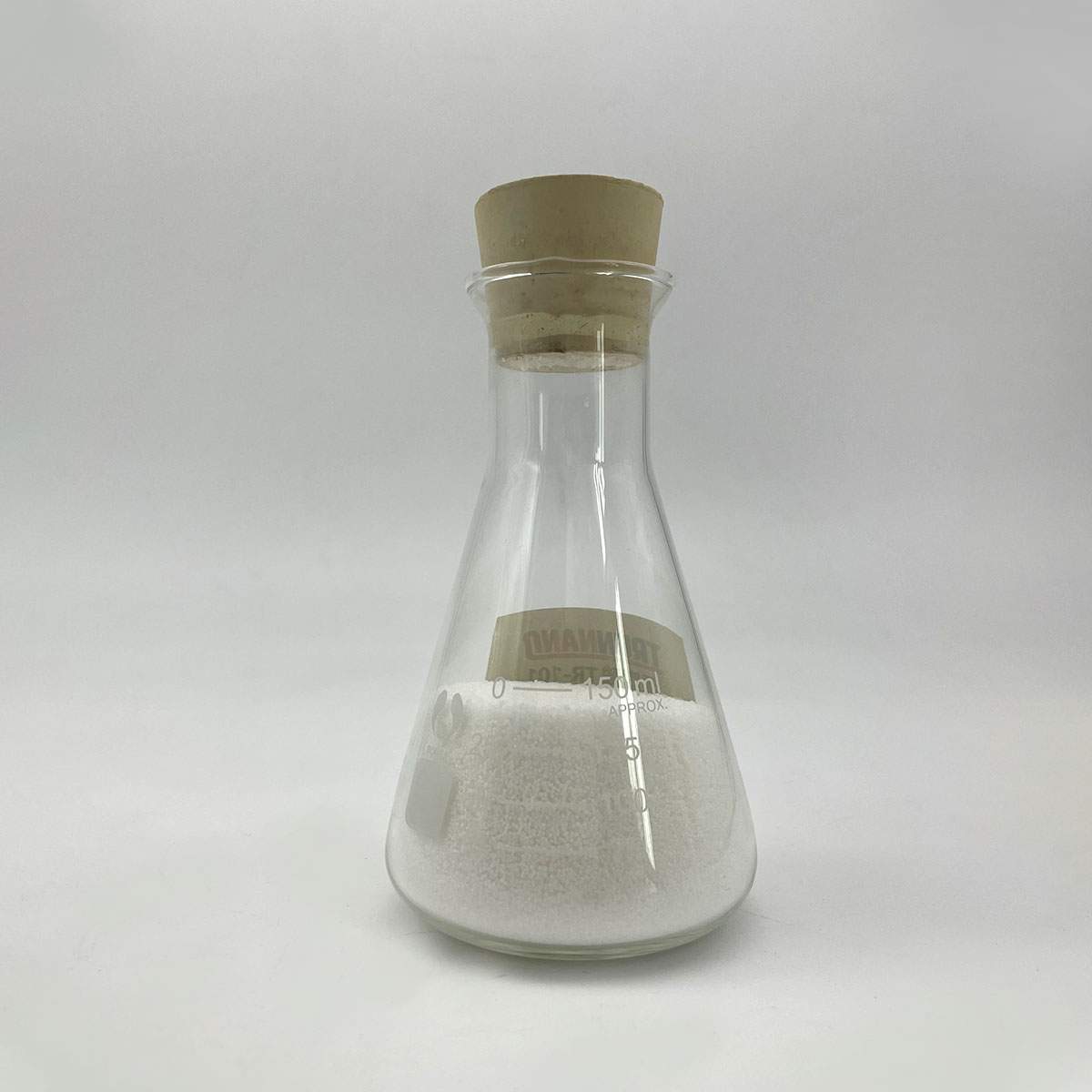

(Hot molybdenum trioxide 99.5%Min MoO3)

Parameters of Hot molybdenum trioxide 99.5%Min MoO3

Molybdenum trioxide (MoO3), a high-purity compound with a minimum content of 99.5%, is an essential material in various industries due to its unique properties and versatile applications. This inorganic compound, which consists of molybdenum atoms bonded with oxygen atoms, holds significant importance in chemical, metallurgical, and electronic sectors.

At its core, molybdenum trioxide is a black or yellowish-brown crystalline solid, characterized by its amphoteric nature. It can act as both an acid and a base, depending on the reaction conditions, making it highly reactive in certain chemical processes. This reactivity is attributed to its ability to donate or accept oxygen ions, making it a key catalyst in various chemical reactions.

In the field of refractories, molybdenum trioxide is widely used as a component in high-temperature materials, such as crucibles, furnace linings, and heat-resistant coatings. Its exceptional thermal stability and resistance to molten metals make it ideal for resisting corrosion and wear in demanding industrial environments.

In the metal production industry, it serves as a crucial additive in steel and other alloys. Molybdenum oxide improves the mechanical properties of these alloys, including strength, toughness, and resistance to high temperatures and corrosive environments. It enhances the formation of hard carbides at grain boundaries, which results in better wear resistance and creep strength.

Moreover, molybdenum trioxide finds applications in the electronics industry, particularly in the fabrication of semiconductor devices. It is used as a dopant in the production of electronic-grade silicon wafers, enhancing their conductivity and enabling the creation of high-performance transistors and integrated circuits.

In the environmental sector, molybdenum trioxide is involved in water treatment processes, where it acts as a coagulant and flocculant to help remove impurities from water sources. Its ability to promote the formation of large, heavy particles makes it useful in clarification and sedimentation steps.

Another area where molybdenum trioxide plays a vital role is in the field of catalysts. It is employed in the production of fertilizers, particularly in the Haber-Bosch process for nitrogen fixation, where it enhances the efficiency of the reaction by lowering the activation energy required.

Lastly, molybdenum trioxide is used in the development of advanced battery technologies, particularly lithium-ion batteries. It serves as a cathode material, contributing to improved energy density and cycle life of these batteries.

In summary, molybdenum trioxide, with a minimum purity of 99.5%, is a versatile material with a myriad of applications across multiple industries. Its unique chemical properties, thermal stability, and catalytic abilities make it a valuable component in refining processes, metal production, electronics, water treatment, and energy storage systems. As research and technology continue to evolve, the importance of high-quality molybdenum trioxide will likely remain steadfast in these diverse applications.

(Hot molybdenum trioxide 99.5%Min MoO3)

FAQs of Hot molybdenum trioxide 99.5%Min MoO3

Inquiry us