Overview of High Purity 99.9% Molybdenum Dioxide MoO2 Powder with whole

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of High Purity 99.9% Molybdenum Dioxide MoO2 Powder with whole

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(High Purity 99.9% Molybdenum Dioxide MoO2 Powder with whole )

Parameters of High Purity 99.9% Molybdenum Dioxide MoO2 Powder with whole

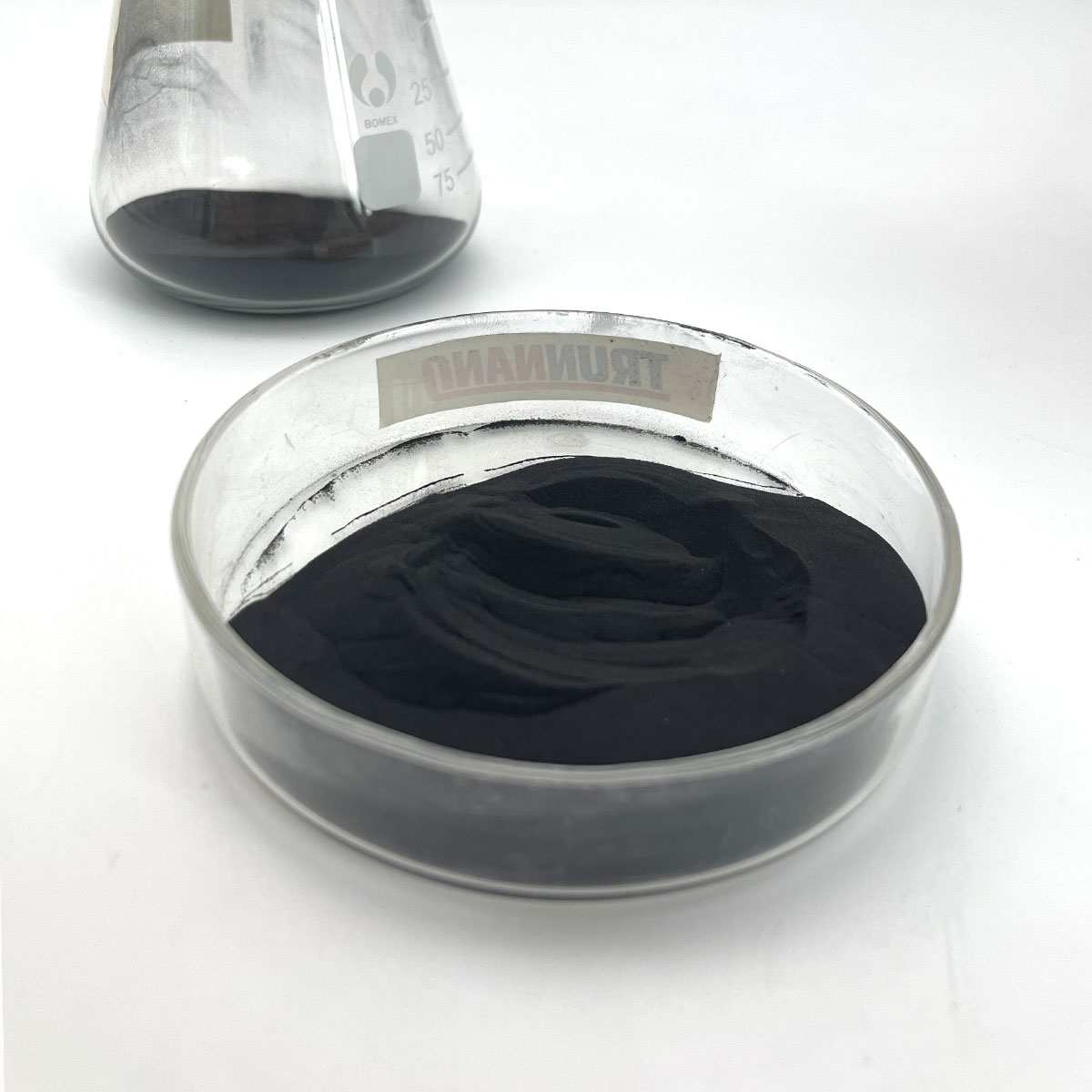

Molybdenum dioxide (MoO2), a compound of molybdenum and oxygen, is a versatile material with a purity level of 99.9%, making it one of the highest quality forms available in the market. This exceptional purity ensures that the material possesses outstanding properties suitable for various applications across multiple industries.

Molybdenum dioxide is formed when molybdenum atoms bond with two oxygen atoms, resulting in a chemical formula of MoO2. The compound crystallizes in a monoclinic structure, characterized by its layered arrangement, which gives it unique electrical, thermal, and catalytic properties. At this high purity level, the crystal structure is highly uniform, minimizing impurities that could otherwise affect performance.

In terms of physical appearance, MoO2 powder appears as a white or off-white, amorphous or crystalline material, depending on the manufacturing process. It has a low density, typically around 5 to 6 g/cm³, which makes it lightweight and easy to handle. The particle size can vary, but high purity grades often offer a narrow distribution, ensuring consistent performance in downstream processes.

One of the key features of molybdenum dioxide is its high thermal stability. It maintains its integrity over a wide temperature range, from cryogenic (-183°C) to elevated temperatures (up to 1,700°C). This property makes it an ideal catalyst support in high-temperature applications, such as automotive exhaust systems and industrial furnaces.

Catalytic activity is another crucial aspect of MoO2, particularly in the field of chemical reactions. As a strong acid catalyst, it exhibits exceptional selectivity in various oxidation processes, including the conversion of hydrocarbons and organic compounds. Its ability to form stable surface oxide films also contributes to its effectiveness in heterogeneous catalysis.

In electronics, molybdenum dioxide finds application as a conductive thin film, due to its moderate conductivity and insulating properties. It is used in microelectronic devices, sensors, and even transparent conducting electrodes in touchscreens and solar cells.

In the energy sector, MoO2 is employed as a cathode material in lithium-ion batteries, where it provides high energy density and long cycle life. Its electrochemical stability makes it suitable for advanced battery technologies, contributing to the development of more efficient and sustainable power sources.

Furthermore, molybdenum dioxide is investigated for its potential use in photocatalysis, where it can harness sunlight to drive chemical reactions. Its bandgap energy aligns well with solar radiation, allowing it to absorb light and facilitate water splitting or other environmentally friendly processes.

In summary, 99.9% pure molybdenum dioxide is a highly sought-after material due to its exceptional purity, robust structure, and versatile properties. Its applications span across industries, from automotive catalysis to electronics and renewable energy, demonstrating the value it brings to modern technology. With its inherent characteristics, high purity MoO2 continues to be a critical component in driving innovation and advancements in various fields.

(High Purity 99.9% Molybdenum Dioxide MoO2 Powder with whole )

FAQs of High Purity 99.9% Molybdenum Dioxide MoO2 Powder with whole

Inquiry us