Overview of Titanium anode hangers are used for anodizing titanium oxide hangers point stick dish racks titanium jigs anodi electroplazing

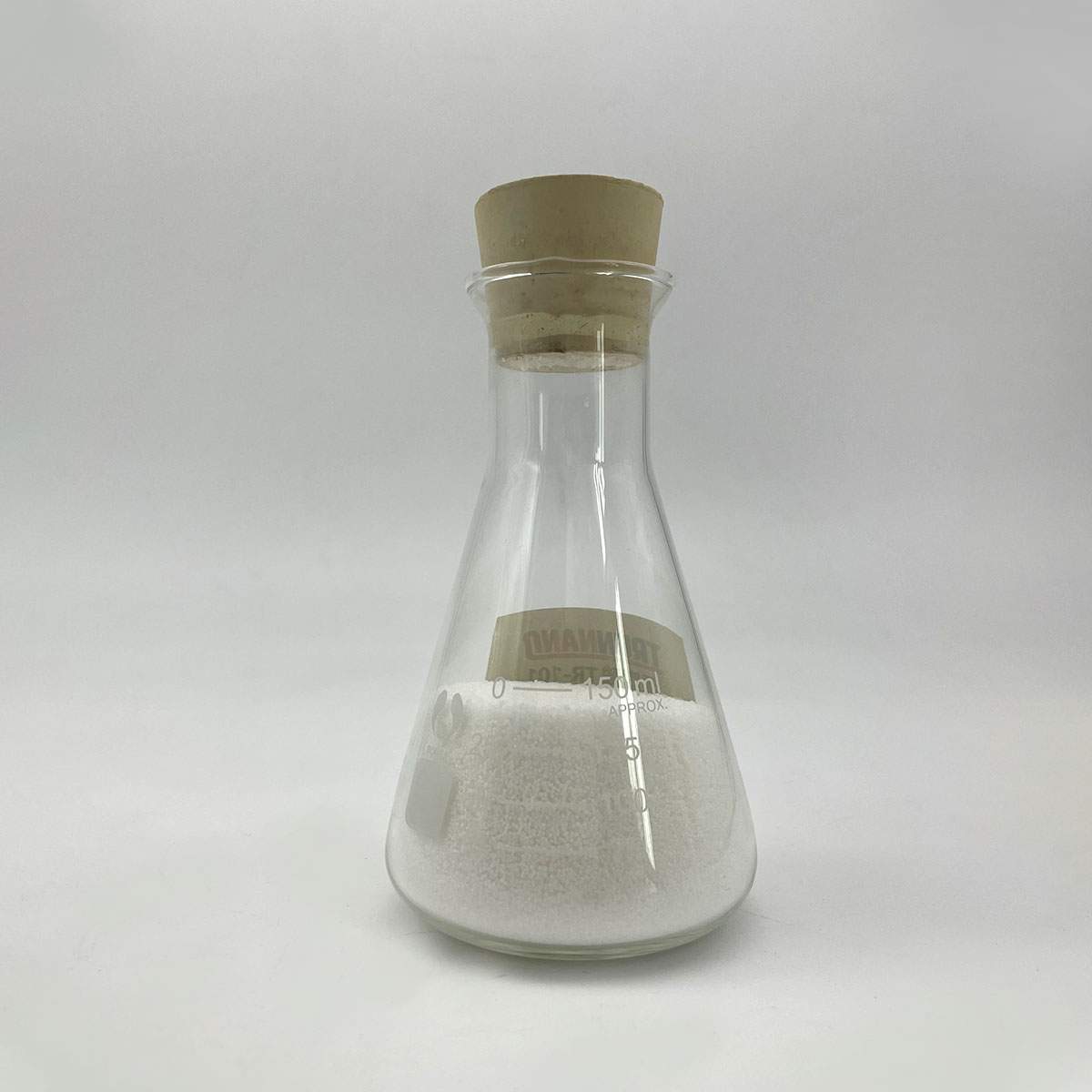

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Titanium anode hangers are used for anodizing titanium oxide hangers point stick dish racks titanium jigs anodi electroplazing

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Titanium anode hangers are used for anodizing titanium oxide hangers point stick dish racks titanium jigs anodi electroplazing)

Parameters of Titanium anode hangers are used for anodizing titanium oxide hangers point stick dish racks titanium jigs anodi electroplazing

Titanium anode hangers are specialized components employed in various industrial processes involving the surface treatment of titanium metal, primarily for anodizing. Anodizing is an electrochemical process that enhances the durability, corrosion resistance, and aesthetic appeal of titanium by depositing a thin, hard, and adherent oxide layer on its surface. This process is widely used in applications such as aerospace, medical implants, automotive parts, and even household items like dish racks and jigs.

The primary function of titanium anode hangers is to facilitate the anodizing process by providing a stable platform or support structure for the titanium components to be treated. These hangers are designed with specific features that ensure efficient current distribution, even heating, and minimal stress on the material being anodized. The choice of materials for anode hangers is crucial, as they must be electrically conductive, chemically inert, and able to withstand high temperatures without compromising their structural integrity.

During the anodizing process, the titanium workpiece is connected to the titanium anode hanger, which acts as the positive electrode in a galvanic cell. The electrolyte solution, typically containing sulfuric acid, is circulated around the assembly, allowing the formation of a uniform oxide layer. As the electrical current flows through the electrolyte, it reacts with the titanium, causing the release of oxygen ions, which then bond with the metal’s surface to form the oxide layer.

Anode hangers may come in different shapes and sizes, depending on the specific application requirements. They may be designed with adjustable clamps or clips to accommodate varying workpiece dimensions, or they may have built-in cooling systems to prevent overheating. Some hangers may also incorporate drainage channels to facilitate the removal of waste products generated during the process.

In addition to the standard anodizing process, titanium anode hangers can also be used in other electroplating techniques, such as electroless nickel plating or hard chrome plating, where a similar setup is required to hold the workpieces in place. These electroplating methods can provide additional surface properties, such as increased wear resistance or improved aesthetics.

The parameters affecting the effectiveness of titanium anode hangers include the voltage applied, the electrolyte concentration, temperature control, and the duration of the process. Proper control of these factors ensures consistent quality and thickness of the oxide layer, which is essential for the desired performance characteristics of the finished product.

In summary, titanium anode hangers play a vital role in the anodizing and electroplating processes for titanium components. Their design and functionality contribute to the successful formation of a durable, corrosion-resistant oxide layer, making them an indispensable component in industries that rely on the unique properties of titanium. By optimizing the process parameters and selecting appropriate hangers, manufacturers can achieve high-quality results while maintaining efficiency and productivity.

(Titanium anode hangers are used for anodizing titanium oxide hangers point stick dish racks titanium jigs anodi electroplazing)

FAQs of Titanium anode hangers are used for anodizing titanium oxide hangers point stick dish racks titanium jigs anodi electroplazing

Inquiry us