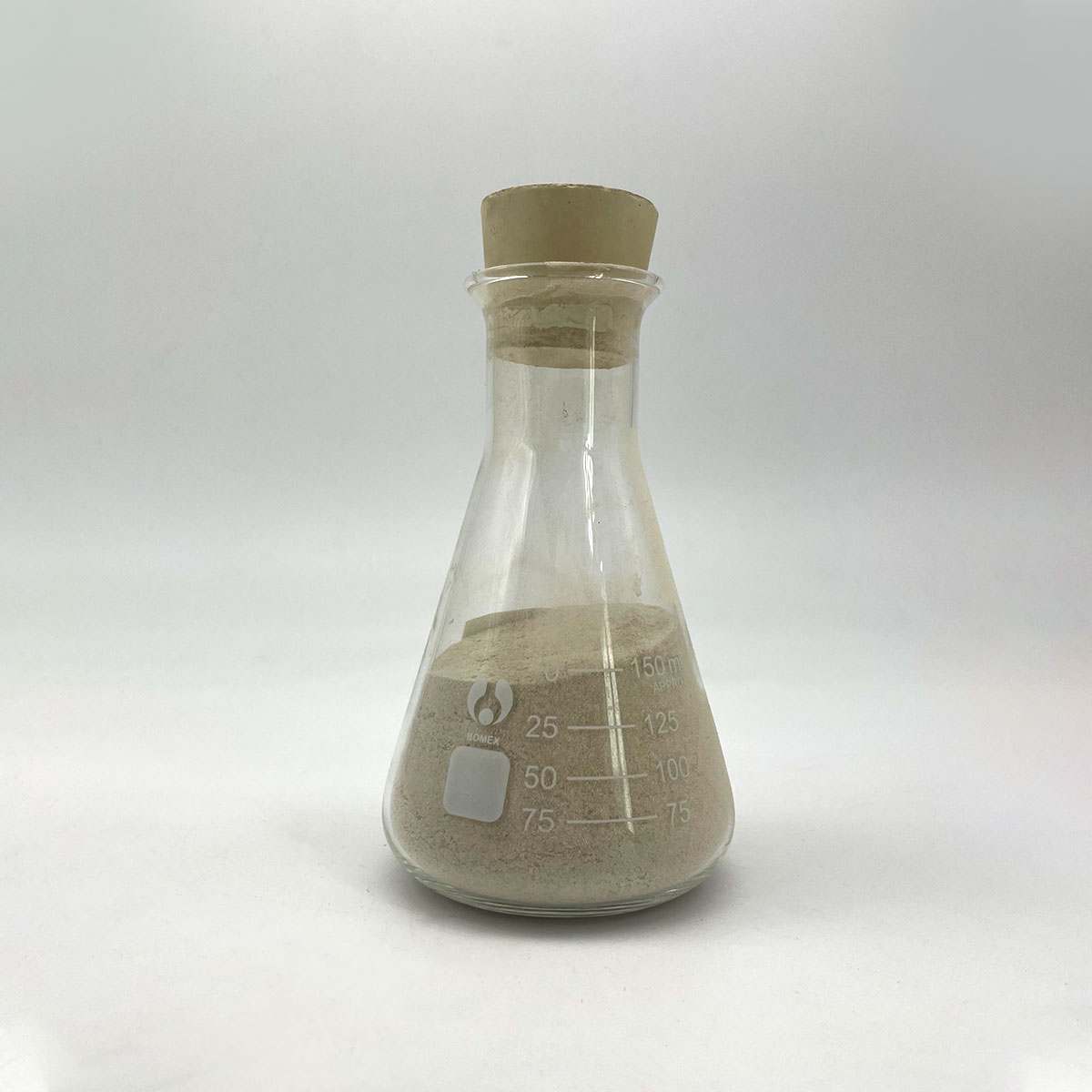

Overview of Sulfate process white pigment TiO2 XM-T288 Titanium Dioxide for solvent based paint

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Sulfate process white pigment TiO2 XM-T288 Titanium Dioxide for solvent based paint

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Sulfate process white pigment TiO2 XM-T288 Titanium Dioxide for solvent based paint)

Parameters of Sulfate process white pigment TiO2 XM-T288 Titanium Dioxide for solvent based paint

The sulfate process, also known as the anatase process, is a widely used method for producing titanium dioxide (TiO2), specifically the high-quality pigment XM-T288, which is highly sought after in solvent-based paints due to its exceptional properties. Titanium dioxide, with its chemical formula TiO2, is a versatile and essential component in various industries, including coatings, cosmetics, and even sunscreen, thanks to its excellent lightfastness, opacity, and whitening abilities.

XM-T288, in particular, stands out for its unique characteristics that make it ideal for solvent-based paints. It is an anatase form of TiO2, which is a crystal structure that imparts a bright, vivid white color and high refractive index, resulting in a superior whiteness and color rendering. The sulfate process ensures that this pigment has a high degree of purity, typically above 99%, reducing impurities that can affect paint performance.

One of the key features of XM-T288 is its excellent dispersion, allowing it to blend seamlessly into the paint matrix without creating visible particles or affecting the paint’s flow properties. This is crucial for achieving a smooth, even finish on various substrates. The pigment’s particle size distribution is carefully controlled during the manufacturing process, typically falling within the range of 5-10 nanometers, which contributes to its superior coverage and hiding power.

In terms of chemical stability, XM-T288 exhibits high resistance to fading and yellowing when exposed to ultraviolet (UV) radiation, which is critical for maintaining the longevity and aesthetic appeal of painted surfaces over time. This property is particularly important for exterior applications where paints are subjected to harsh environmental conditions.

Moreover, the sulfate process results in a pigment with low iron content, which minimizes the formation of unwanted brownish hues often associated with other TiO2 sources. This reduces the need for additional pigments or colorants, making XM-T288 an economically efficient choice for paint manufacturers.

Another advantage of XM-T288 is its compatibility with various solvents commonly used in solvent-based paints. Its good compatibility ensures that it does not negatively impact the paint’s drying time, adhesion, or overall performance. The pigment’s thermal stability is also noteworthy, allowing it to maintain its integrity during the paint curing process without degradation.

Lastly, the sulfate process produces a pigment with a high specific surface area, which contributes to its ability to adsorb dyes and pigments, enhancing the paint’s color depth and vibrancy. This feature is particularly valuable in formulations where vibrant colors are desired.

In summary, the sulfate process-derived titanium dioxide pigment XM-T288 is a premium choice for solvent-based paints due to its excellent dispersion, high refractive index, UV resistance, chemical stability, compatibility, and ability to enhance color intensity. These attributes make it an indispensable ingredient in ensuring the quality, durability, and visual appeal of the final paint product.

(Sulfate process white pigment TiO2 XM-T288 Titanium Dioxide for solvent based paint)

FAQs of Sulfate process white pigment TiO2 XM-T288 Titanium Dioxide for solvent based paint

Inquiry us