Overview of Made in China suoyi 99.9 3N Niobium Pentoxide 4N (99.99%) used for production of niobium CAS 1313-96-8

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Made in China suoyi 99.9 3N Niobium Pentoxide 4N (99.99%) used for production of niobium CAS 1313-96-8

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Made in China suoyi 99.9 3N Niobium Pentoxide 4N (99.99%) used for production of niobium CAS 1313-96-8)

Parameters of Made in China suoyi 99.9 3N Niobium Pentoxide 4N (99.99%) used for production of niobium CAS 1313-96-8

Title: High Purity Niobium Pentoxide (Nb2O5) – A Key Ingredient in the Manufacturing of Niobium (CAS 1313-96-8)

Introduction

Niobium Pentoxide, also known as Nb2O5 or niobium oxide, is a versatile chemical compound with the chemical formula Nb2O5 and the CAS number 1313-96-8. It is an essential material in various industries, particularly in the production of niobium, a rare and strategic metal with exceptional properties that make it indispensable in numerous high-tech applications. This article delves into the significance of 99.9% and 4N (99.99%) purity grades, their manufacturing process, and the role they play in the manufacturing of niobium.

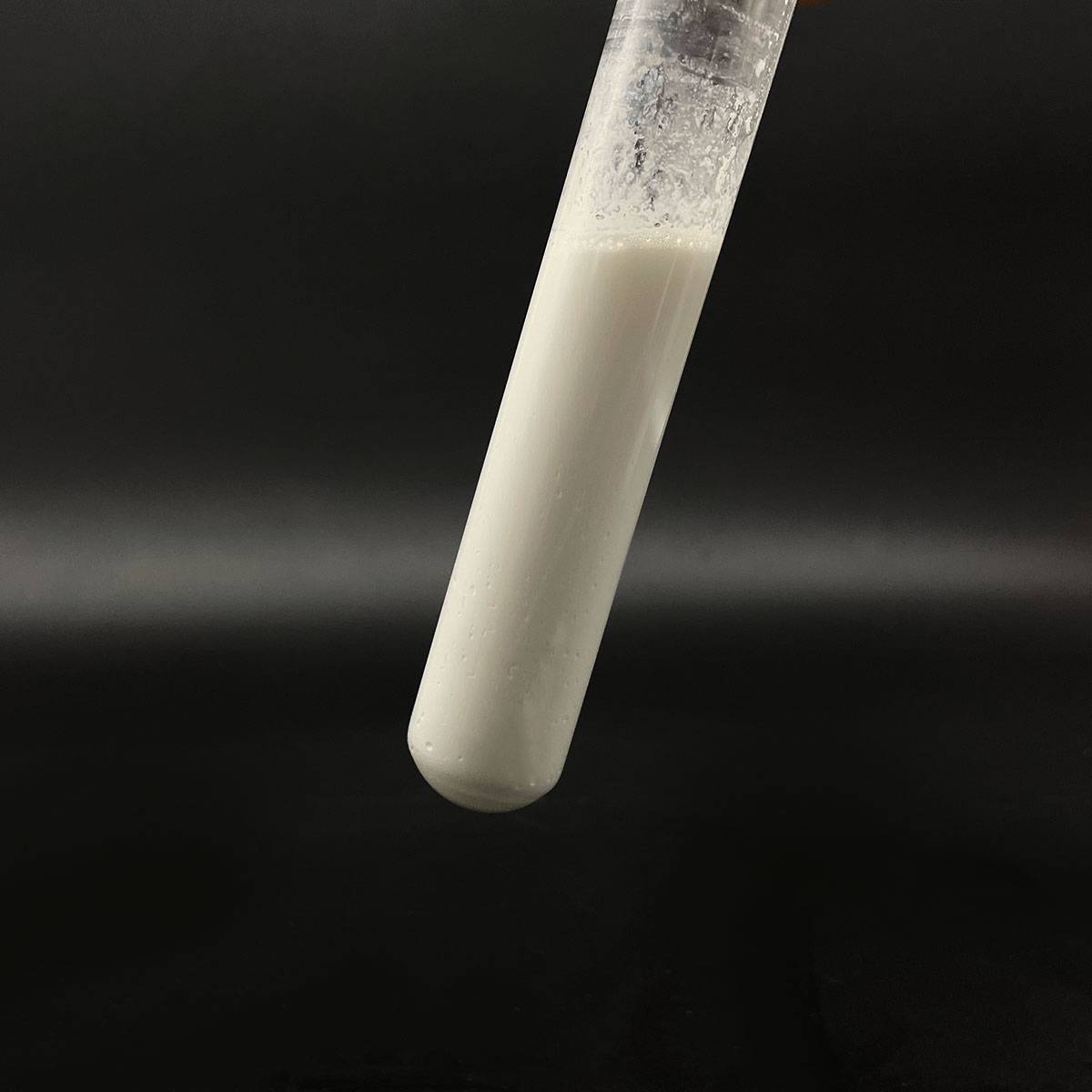

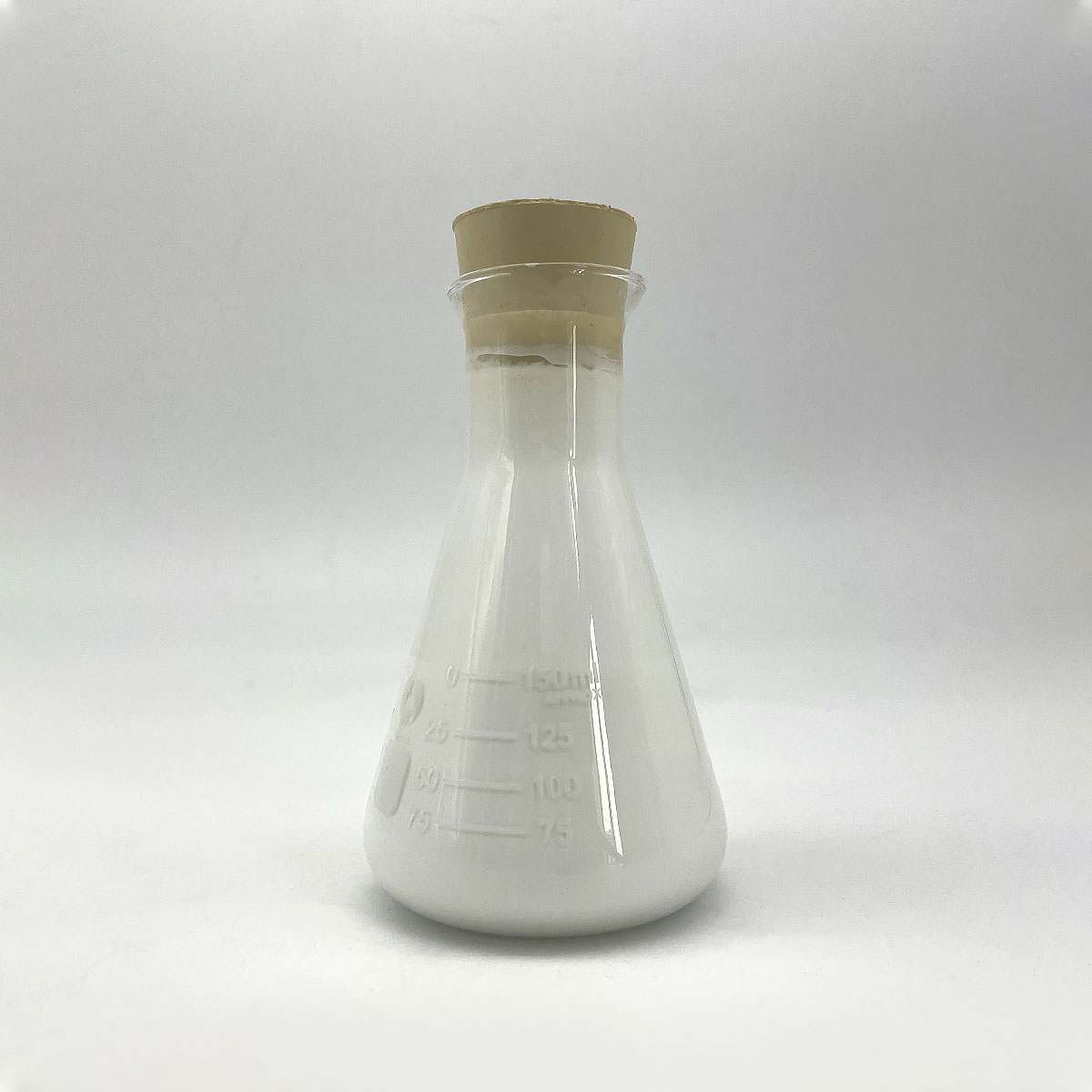

Properties and Importance

Niobium Pentoxide is a white, crystalline solid, which is amphoteric in nature, meaning it can react with both acids and alkalis. Its high purity levels, such as 99.9% (3N) and 99.99% (4N), ensure that it possesses exceptional chemical stability and minimal impurities, making it suitable for demanding applications. The 4N grade, in particular, is sought after for its ultra-high purity, enabling it to maintain the desired properties of the final niobium product.

Manufacturing Process

The production of 99.9% and 4N Niobium Pentoxide begins with the extraction of niobium from its primary sources, primarily from minerals like columbite-tantalite (coltan) and pyrochlore. The refining process involves several stages, including:

1. Mining and Concentration: Raw materials are mined, crushed, and separated to concentrate niobium-rich ores.

2. Smelting: The concentrated ore is processed through smelting to extract the metallic niobium, which is then combined with oxygen to form a niobium oxide slag.

3. Refining: The slag containing Nb2O5 is subjected to chemical leaching and purification methods, such as acid digestion, followed by precipitation and filtration to obtain a crude niobium pentoxide product.

4. Purification: To achieve the desired purity levels, the crude Nb2O5 undergoes further purification through techniques like sublimation, zone refining, or electrolysis. For 4N purity, this process is particularly rigorous to remove trace amounts of impurities.

5. Drying and Formulation: The purified Nb2O5 is then dried and may be formulated into powders, pellets, or other forms, depending on the application requirements.

Applications in Niobium Production

Niobium Pentoxide serves as a critical precursor in the production of high-purity niobium metal. It is used in the reduction process, where it reacts with carbon or hydrogen at high temperatures to form niobium metal. The purity of the niobium oxide directly influences the quality and properties of the final niobium product, which finds applications in diverse sectors:

– Aerospace: Niobium is used in lightweight structures due to its high strength-to-weight ratio and resistance to corrosion, particularly in jet engines and airframes.

– Electronics: Niobium is a key component in superconducting magnets, radio-frequency (RF) devices, and microwave technology.

– Nuclear Industry: Niobium is employed in nuclear reactors as a cladding material due to its excellent thermal conductivity and resistance to neutron radiation.

– Energy: Niobium is utilized in the production of high-efficiency transformers and power cables.

Conclusion

In summary, 99.9% (3N) and 4N (99.99%) pure Niobium Pentoxide are essential ingredients in the manufacturing of niobium, a versatile metal with remarkable properties. The rigorous purification processes ensure that these grades meet the stringent demands of various industries, contributing to the development of cutting-edge technologies. As the demand for niobium continues to grow, maintaining high purity levels will remain crucial for the performance and reliability of products utilizing this remarkable metal.

(Made in China suoyi 99.9 3N Niobium Pentoxide 4N (99.99%) used for production of niobium CAS 1313-96-8)

FAQs of Made in China suoyi 99.9 3N Niobium Pentoxide 4N (99.99%) used for production of niobium CAS 1313-96-8

Inquiry us