Overview of Spherical Niobium C103 Alloy Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Spherical Niobium C103 Alloy Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

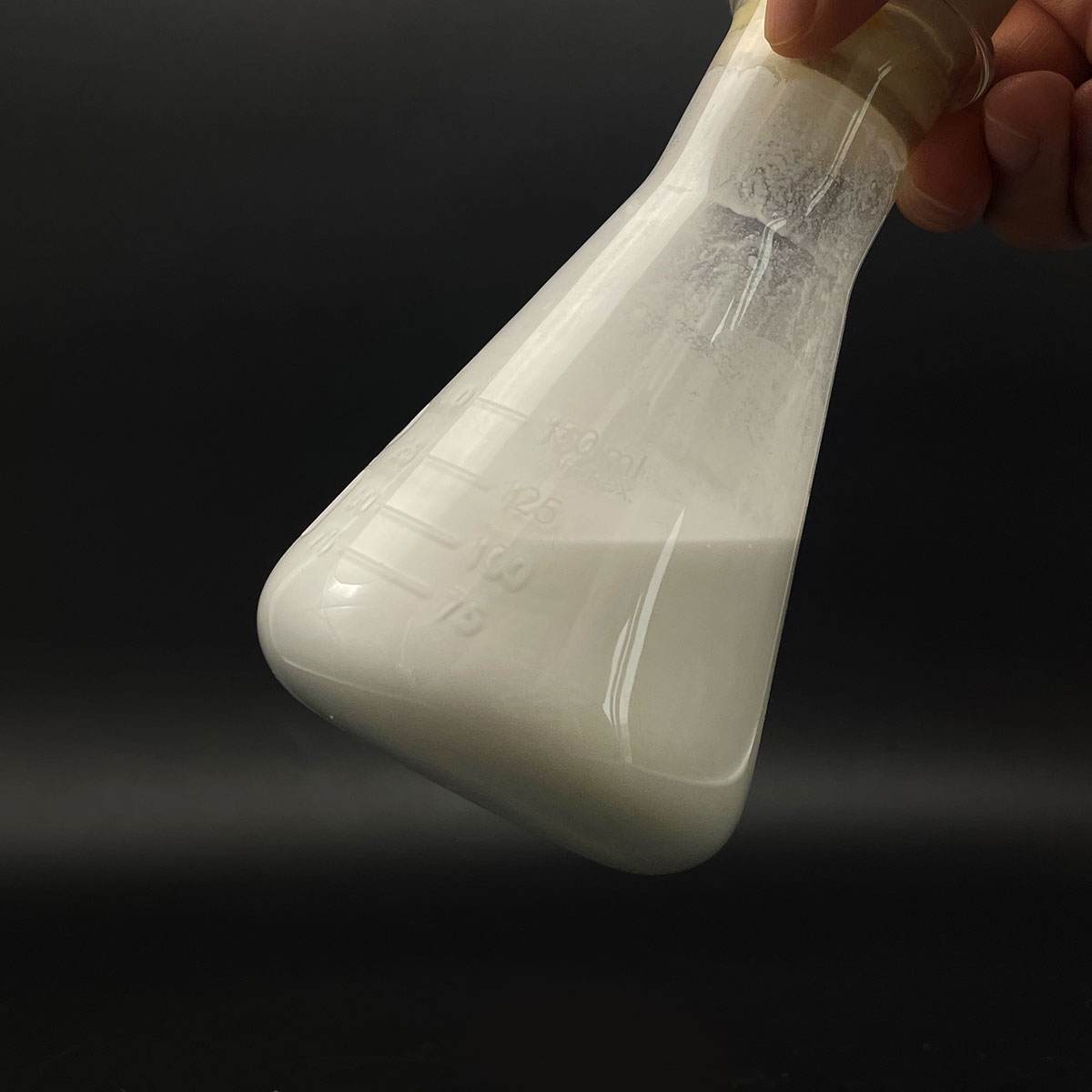

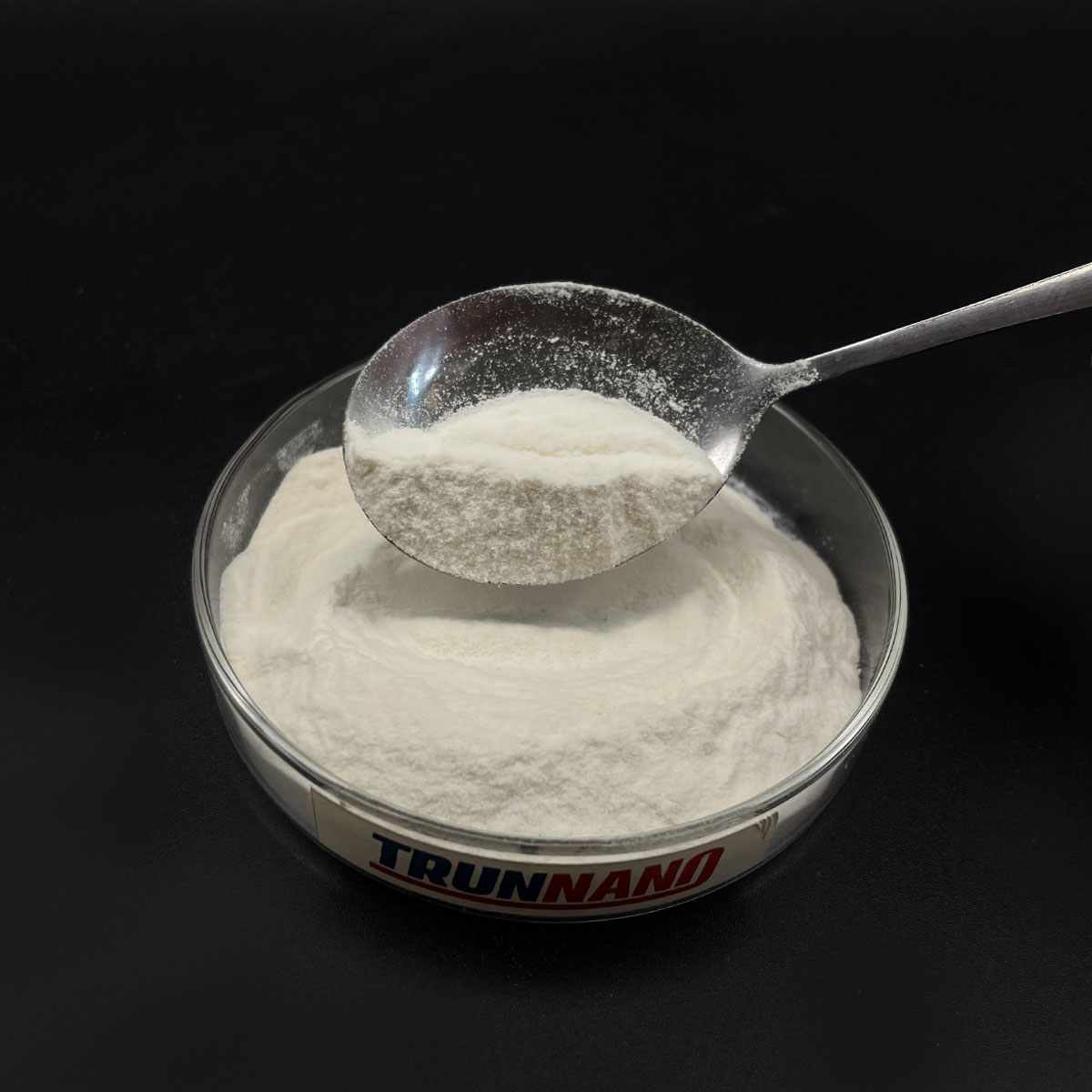

(Spherical Niobium C103 Alloy Powder)

Parameters of Spherical Niobium C103 Alloy Powder

Spherical Niobium C103 alloy powder is a high-performance material that finds extensive applications in various industries, particularly in the fields of aerospace, nuclear energy, and superconducting technologies. The C103 grade, which stands for a specific composition, denotes a niobium-based alloy that exhibits exceptional properties such as high strength, excellent corrosion resistance, and superior mechanical stability.

Niobium C103 alloy powder is characterized by its unique manufacturing process, which results in particles with spherical shapes. This morphology offers several advantages over other forms of powders, including improved flowability, reduced agglomeration, and enhanced packing density. The spherical shape allows for more efficient use of the material during consolidation processes like sintering or melting, leading to better densification and fewer defects.

The primary component of the C103 alloy is niobium (Nb), which constitutes around 90% of the total weight. Additional elements like titanium (Ti), aluminum (Al), and sometimes vanadium (V) or zirconium (Zr) are added to enhance the alloy’s properties. These trace elements contribute to the material’s strength, ductility, and resistance to creep deformation under high temperatures. The precise chemical composition ensures a balance between strength and processability, making it suitable for demanding applications.

One of the key features of Niobium C103 is its excellent thermal conductivity, which makes it an ideal choice for heat transfer components in cryogenic systems. Its ability to maintain superconductivity below a certain critical temperature, typically below -200°C, allows for efficient energy transmission with minimal loss. This property is crucial in applications like magnetic resonance imaging (MRI) machines and high-speed particle accelerators.

The alloy’s corrosion resistance is another standout feature. Niobium C103 can withstand harsh environments, protecting against both atmospheric corrosion and aggressive chemicals. This durability extends the service life of components and reduces maintenance requirements, which is particularly important in industries like nuclear power where materials must endure long-term exposure to radiation.

In terms of mechanical properties, Niobium C103 possesses high strength-to-weight ratio, making it lightweight yet strong. This combination enables the fabrication of lightweight, yet structurally robust components, which is beneficial in aerospace and automotive industries. Additionally, the alloy’s good formability allows for easy shaping into complex geometries without significant loss of strength.

The production of Niobium C103 alloy powder involves a combination of techniques, such as gas atomization, milling, or spray-drying, to achieve the desired particle size distribution and spherical shape. These processes ensure a consistent quality across batches and enable fine control over the final product’s characteristics.

In summary, Niobium C103 alloy powder is a versatile material with outstanding properties that make it an indispensable choice in various industries. Its spherical shape, high strength, corrosion resistance, and thermal conductivity make it well-suited for applications ranging from superconductors to aerospace components. As technology continues to advance, the demand for this unique material is likely to grow, driving further research and development in the field.

(Spherical Niobium C103 Alloy Powder)

FAQs of Spherical Niobium C103 Alloy Powder

Inquiry us