Overview of High purity Niobium nitride NbN powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of High purity Niobium nitride NbN powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

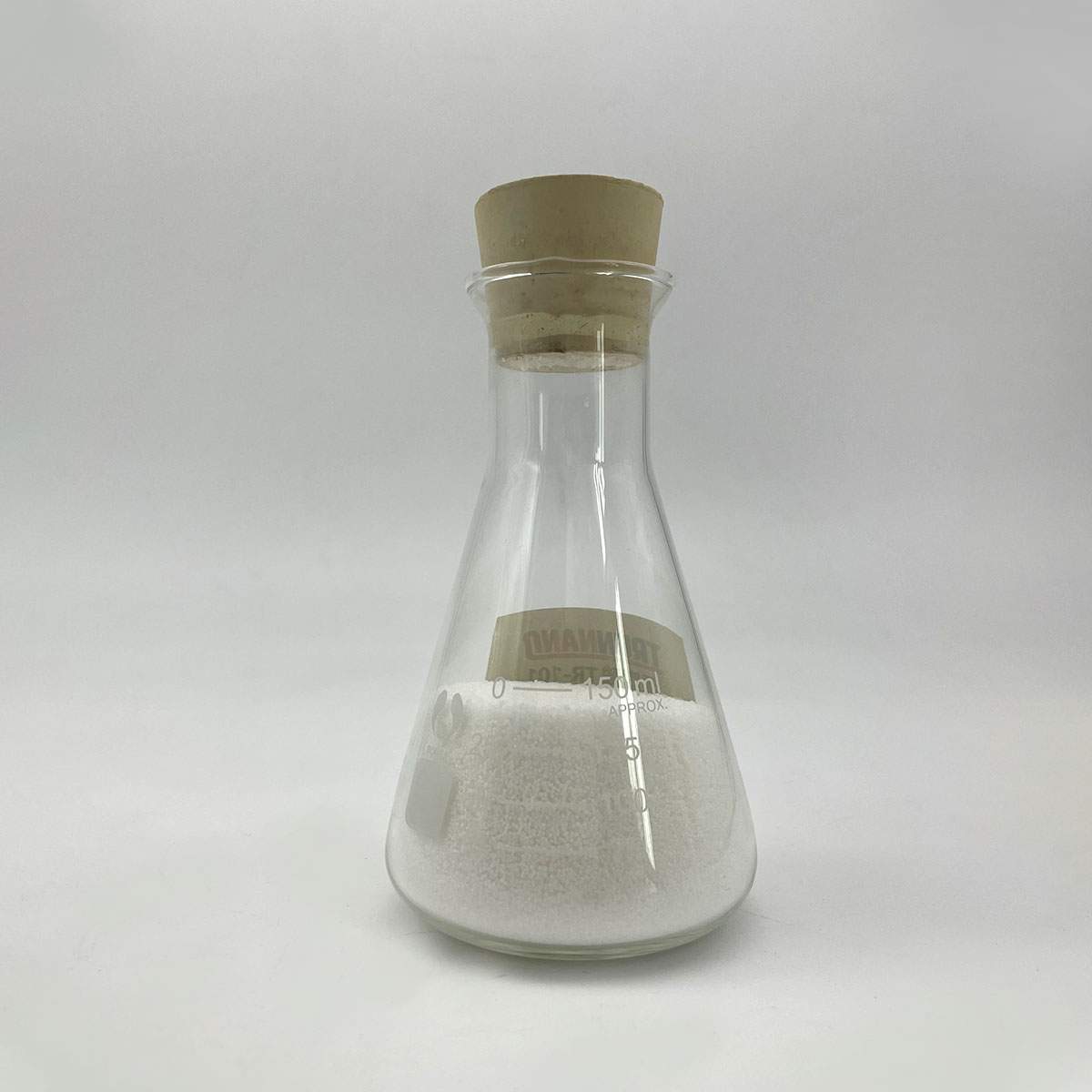

(High purity Niobium nitride NbN powder)

Parameters of High purity Niobium nitride NbN powder

Niobium Nitride (NbN) is a technologically advanced ceramic material that has gained significant attention due to its exceptional properties, primarily in the field of superconductivity and electronic applications. As a high purity form of NbN powder, it exhibits remarkable characteristics that make it a sought-after material in various industries.

Starting with the chemical composition, NbN is a binary compound composed of niobium (Nb), a rare earth element, and nitrogen (N). The stoichiometry is typically 1:1, ensuring a consistent and pure mixture. The purity level of the NbN powder plays a crucial role in its performance, and high purity grades like 99.99% or even 99.999% are commonly used to minimize impurities that could affect the material’s properties.

The physical properties of NbN powder are noteworthy. It has a hexagonal crystal structure, belonging to the wurtzite family, which gives it a high melting point around 1,650°C (3,002°F). This high thermal stability makes it suitable for applications where resistance to elevated temperatures is essential. Its density is relatively low, approximately 6.2 g/cm³, making it lightweight and easy to handle.

One of the most prominent features of NbN is its superconducting behavior. When cooled below a certain critical temperature (Tc), typically around 12-16 K (-157.2 to -139.2°C), it transitions into a zero-resistance state, enabling efficient electrical current flow without energy loss. This property makes it ideal for applications in magnetic resonance imaging (MRI), power transmission, and microwave devices.

In terms of mechanical properties, NbN is known for its high strength and hardness compared to other ceramic materials. It exhibits good wear resistance and low friction coefficients, which are beneficial for wear-resistant coatings and bearings. Additionally, its high thermal conductivity, around 250 W/m·K, aids in efficient heat dissipation, a critical aspect in electronic components.

Processing and synthesis techniques play a vital role in obtaining high purity NbN powder. Common methods include chemical vapor deposition (CVD), sputtering, and reactive evaporation. These processes ensure the formation of fine particles with uniform size distribution, ranging from submicron to micron scales, depending on the application requirements.

The surface finish and particle morphology of the NbN powder are also essential factors. A smooth surface ensures better adhesion during sintering and reduces defects in the final product. Depending on the application, the powder may be ball milled to achieve a desired particle shape and reduce grain boundaries, enhancing the material’s overall performance.

In conclusion, high purity NbN powder is a versatile material with unique properties that make it an attractive choice for various technological applications. Its combination of superconductivity, thermal stability, mechanical strength, and excellent electrical conductivity sets it apart from conventional materials. With ongoing research and development, the potential for NbN to revolutionize sectors such as electronics, energy, and transportation continues to grow.

(High purity Niobium nitride NbN powder)

FAQs of High purity Niobium nitride NbN powder

Inquiry us