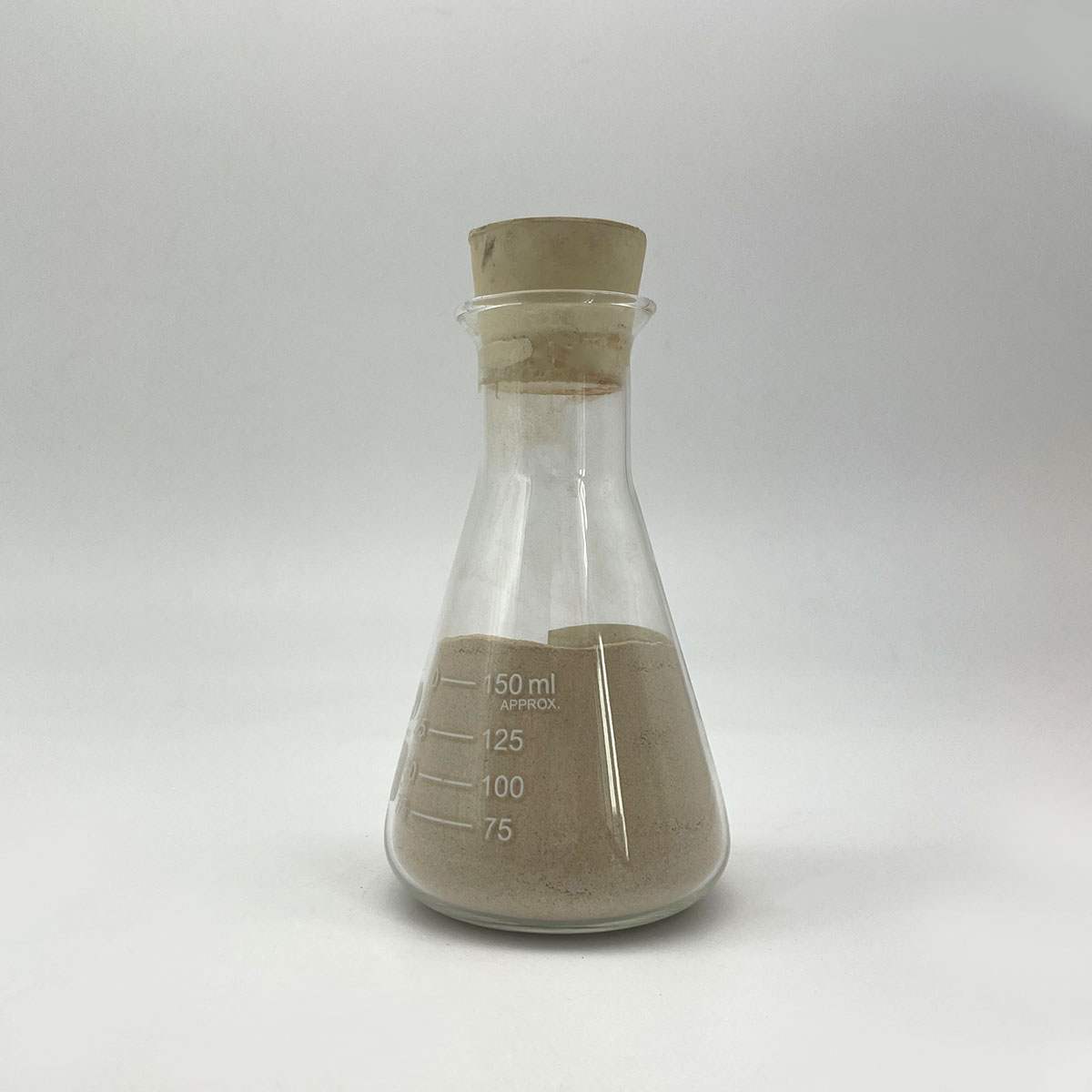

Overview of Factory Niobium Powder with Nb and CAS No 7440-03-1

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Factory Niobium Powder with Nb and CAS No 7440-03-1

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Factory Niobium Powder with Nb and CAS No 7440-03-1)

Parameters of Factory Niobium Powder with Nb and CAS No 7440-03-1

Niobium powder, also known by its chemical symbol Nb and CAS number 7440-03-1, is a high-purity metallic compound that plays a crucial role in various industries due to its unique properties. This fine, powdery form of niobium is derived through a sophisticated manufacturing process, which involves refining niobium ore, typically found in minerals like columbite and pyrochlore.

The extraction of niobium begins with mining, where the ores containing niobium are extracted from the earth. These ores are then crushed and processed to concentrate the niobium content. The purification process involves multiple stages, including smelting, leaching, and solvent extraction, to remove impurities such as iron, titanium, and other elements. Once the crude niobium is refined, it undergoes further purification to achieve the high purity level required for niobium powder.

The production of niobium powder requires advanced milling techniques, which can include ball milling or attrition milling, to reduce the metal into a fine, uniform particle size. This size is critical for different applications, as it influences the powder’s reactivity, strength, and overall performance. The milling process is often followed by sieving and classification to ensure a consistent particle distribution.

Niobium powder finds extensive use in various sectors, including aerospace, nuclear energy, and electronics. Its superconducting properties at low temperatures make it an essential component in the development of cutting-edge technologies like MRI machines, particle accelerators, and fusion reactors. Its high strength-to-weight ratio makes it suitable for lightweight yet strong components in aircraft and spacecraft structures.

In the chemical industry, niobium is employed as a catalyst in the production of certain chemicals, enhancing reaction rates and selectivity. Additionally, it is used in the production of refractory materials, which are resistant to high temperatures, for applications in furnaces and industrial crucibles.

In the field of superalloys, niobium powder is combined with other metals like titanium, aluminum, and chromium to create high-performance alloys used in gas turbines, jet engines, and aerospace components. These alloys exhibit exceptional heat resistance, corrosion resistance, and mechanical strength.

Moreover, niobium is a key ingredient in the production of precision instruments and tools, where its non-magnetic properties are advantageous. It is also utilized in the creation of medical implants, where biocompatibility and corrosion resistance are paramount.

In summary, niobium powder with CAS number 7440-03-1 is a high-quality material derived through a complex manufacturing process. Its unique properties make it indispensable in numerous industries, ranging from aerospace and nuclear technology to chemical catalysts and biomedical applications. The fine particle size and purity of this product ensure optimal performance in various demanding environments, highlighting its versatility and importance in modern technology.

(Factory Niobium Powder with Nb and CAS No 7440-03-1)

FAQs of Factory Niobium Powder with Nb and CAS No 7440-03-1

Inquiry us