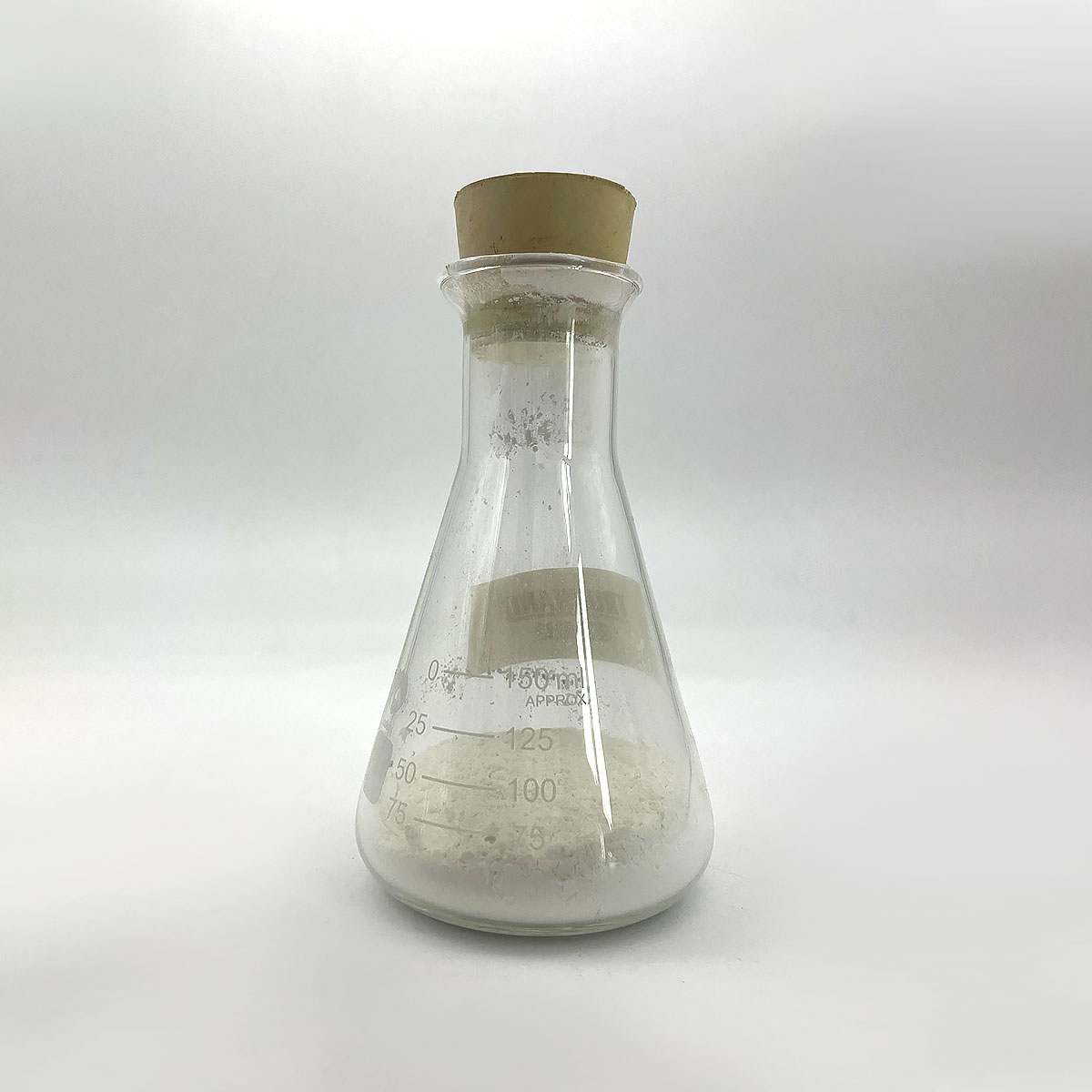

Overview of Niobium powder for metallurgical purposes (e.g. 11m-325mesh,-30/+325mesh) search who demand large

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Niobium powder for metallurgical purposes (e.g. 11m-325mesh,-30/+325mesh) search who demand large

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Niobium powder for metallurgical purposes (e.g. 11m-325mesh,-30/+325mesh) search who demand large)

Parameters of Niobium powder for metallurgical purposes (e.g. 11m-325mesh,-30/+325mesh) search who demand large

Niobium, a chemical element with the symbol Nb and atomic number 41, is a strategic metal known for its unique combination of properties, making it indispensable in various metallurgical applications. Its high strength, corrosion resistance, and superconducting capabilities have attracted significant demand from industries such as aerospace, nuclear power, and energy transmission.

Metallurgical uses of niobium powder, particularly in the form of 11m-325mesh and -30/+325mesh, are driven by their ability to enhance the performance of alloys and composites. The 11m-325mesh size, which corresponds to particles ranging from about 45 microns to 75 microns in diameter, is ideal for applications where a balance between strength and ductility is crucial. This fineness allows for better dispersion in the material, resulting in improved mechanical properties like toughness and fatigue resistance.

The -30/+325mesh size, on the other hand, consists of particles ranging from 44 microns to 63 microns, providing a slightly coarser yet still homogeneous distribution. This grade is often used when a higher packing density or cost-effectiveness is sought, without compromising the overall performance of the niobium-containing material.

Major industries demanding high-quality niobium powder for metallurgical purposes include:

1. Aerospace: Niobium is used in lightweight, high-strength alloys for aircraft structures, missile components, and supersonic engines. The powder’s fine particle sizes enable better bonding and reduced weight, enhancing fuel efficiency and flight performance.

2. Nuclear Power: In nuclear reactors, niobium is essential for its use in superconducting magnets that provide efficient magnetic fields for cooling systems. The precise control over particle size ensures optimal performance and heat transfer capabilities.

3. Energy Transmission: High-voltage transformers and conductors rely on niobium-titanium (NbTi) and niobium-tin (Nb3Sn) alloys for their exceptional electrical conductivity and resistance to electromagnetic heating. The -325mesh powder contributes to the manufacturing of these components, improving efficiency and reliability.

4. Medical Devices: Niobium-based alloys are used in orthopedic implants and cardiovascular devices due to their biocompatibility and low magnetic field interaction. The fine mesh sizes ensure precise shaping and minimal irritation during implantation.

5. Electronics: Niobium is employed in microwave and radio frequency (RF) components due to its low loss tangent, making it an ideal choice for high-frequency circuits. The controlled particle size ensures consistent performance across different devices.

6. Chemical Processing: Niobium is used in catalysts and electrochemical cells, where its fine powder form enables efficient surface area exposure and improved catalytic activity.

In conclusion, the demand for niobium powder in metallurgical applications is driven by its versatile properties and the need for enhanced performance in various sectors. Companies and researchers seeking this material typically require suppliers who can provide consistent quality, controlled particle size distribution, and customization according to specific project requirements. As technology continues to advance, the importance of niobium in modern metallurgy will only grow, making it a critical component in the global industrial landscape.

(Niobium powder for metallurgical purposes (e.g. 11m-325mesh,-30/+325mesh) search who demand large)

FAQs of Niobium powder for metallurgical purposes (e.g. 11m-325mesh,-30/+325mesh) search who demand large

Inquiry us