Overview of FeNb 65/60/55/50 ferro niobium powder lump for welding rods wires and steel with factory

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of FeNb 65/60/55/50 ferro niobium powder lump for welding rods wires and steel with factory

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

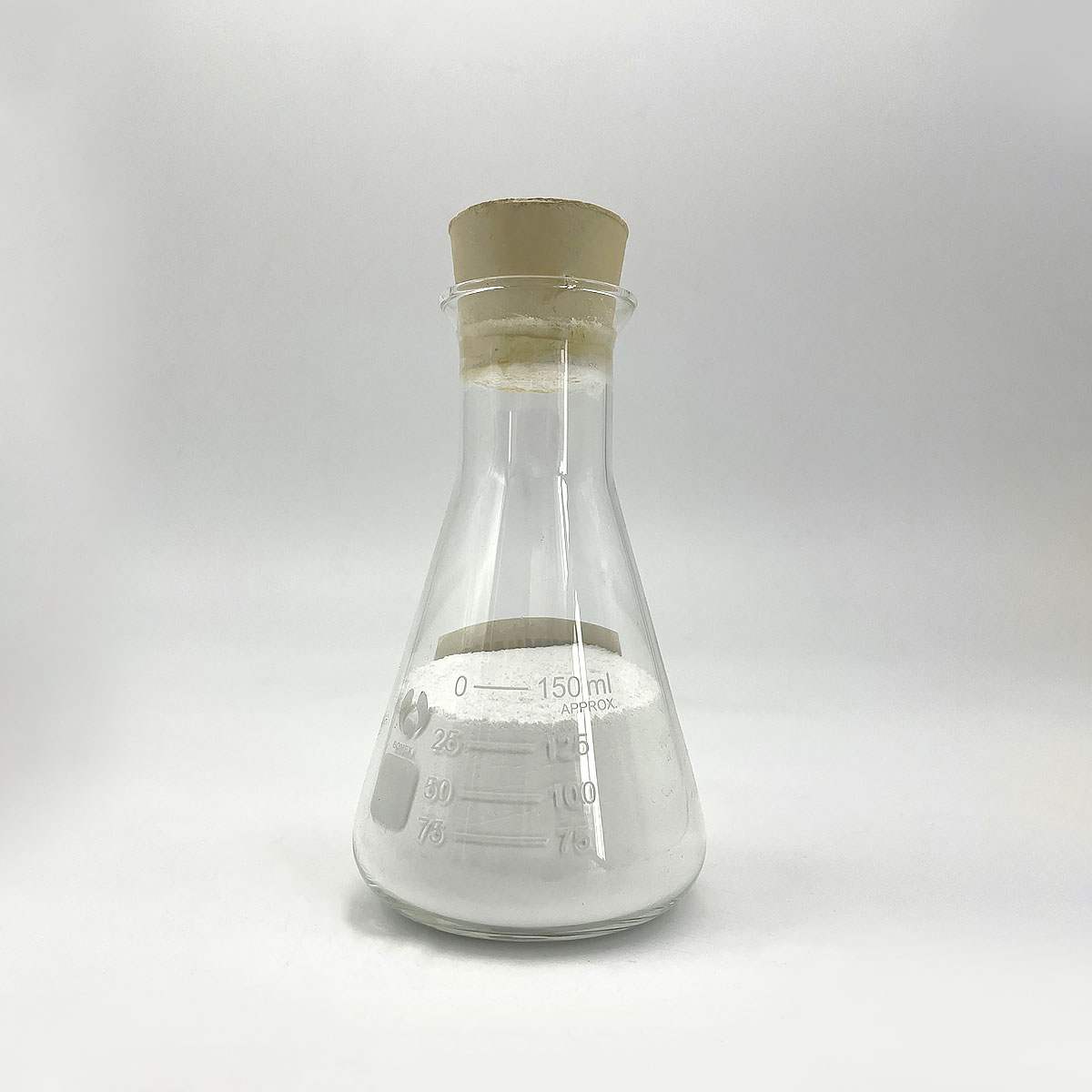

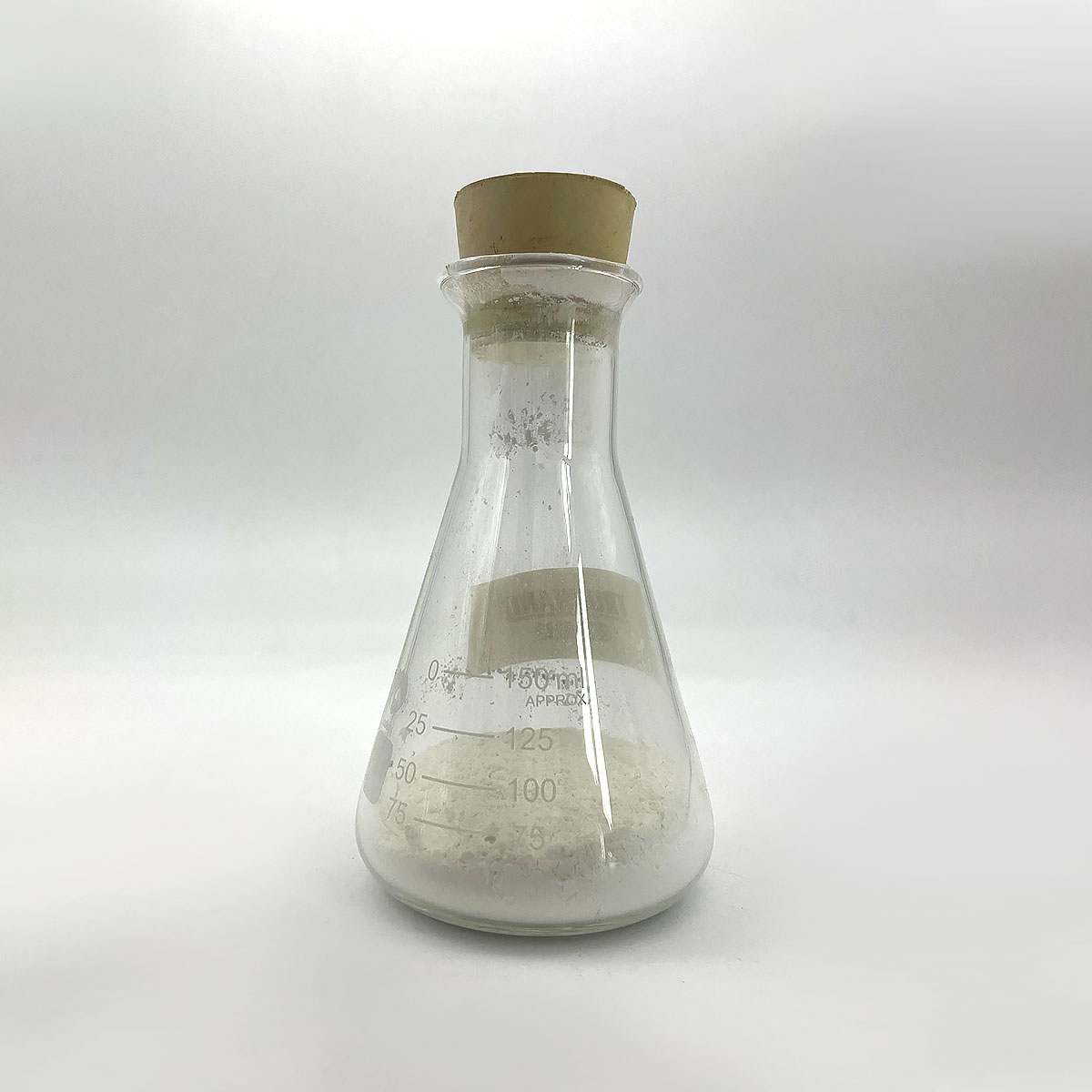

(FeNb 65/60/55/50 ferro niobium powder lump for welding rods wires and steel with factory )

Parameters of FeNb 65/60/55/50 ferro niobium powder lump for welding rods wires and steel with factory

Ferro-Niobium (FeNb) is a high-performance alloy composed primarily of iron (Fe) and niobium (Nb), known for its exceptional properties that make it suitable for various applications, particularly in the welding industry. The FeNb 65/60/55/50 grade refers to a specific composition range, where the percentages indicate the weight fractions of iron, niobium, and potentially other elements such as carbon, manganese, or titanium. This particular blend is designed to offer a balance between strength, ductility, and weldability.

The FeNb 65/60/55/50 powder lump variant is produced as a fine-grained material, which is typically used in the manufacturing of welding rods, wires, and steel products. The powder form allows for precise control over the alloy’s microstructure, enabling improved mechanical properties and consistent performance across different applications.

The factory producing this FeNb powder follows strict quality control measures to ensure the following parameters:

1. Particle Size Distribution: The powder is characterized by a narrow size distribution, ensuring uniformity in the final product. This helps achieve better flow during processing and reduces segregation during melting, leading to a more homogeneous weld.

2. Purity: The purity of the FeNb alloy is critical for maintaining its desired properties. The factory tests the powder for impurities like sulfur, phosphorus, and oxygen, which can negatively impact weld quality.

3. Chemical Composition: The 65/60/55/50 ratio indicates that the manufacturer has targeted a specific chemical composition, ensuring the alloy possesses the necessary balance for optimal performance in welding processes.

4. Microstructure: The powder’s microstructure, including grain size and phase formation, plays a crucial role in determining its mechanical strength and weldability. The factory may use controlled heat treatment to achieve the desired microstructure for best results.

5. Ductility: A higher niobium content in the alloy contributes to increased ductility, allowing the material to deform easily without cracking during welding, which is essential for maintaining structural integrity.

6. Hardness and Toughness: The FeNb 65/60/55/50 grade provides an appropriate balance between hardness and toughness, making it suitable for demanding applications like pressure vessels, aerospace components, and automotive parts.

7. Weldability: The powder is designed to be easily melted and fused during welding, resulting in strong, defect-free joints. The manufacturer may conduct tests to evaluate the alloy’s compatibility with various welding techniques and procedures.

8. Thermal Conductivity: Niobium enhances the thermal conductivity of the Fe-based alloy, facilitating rapid cooling and minimizing heat-affected zones, which can minimize distortion and improve overall welding efficiency.

9. Corrosion Resistance: Depending on the composition, FeNb alloys may exhibit enhanced corrosion resistance, making them suitable for use in marine, chemical, and industrial environments.

In conclusion, the FeNb 65/60/55/50 ferro-niobium powder lump is a specialized material engineered for welding applications, offering a combination of strength, ductility, and weldability. The factory produces this powder with stringent quality control, ensuring that the final product meets the necessary specifications for use in welding rods, wires, and steel fabrication. By maintaining a consistent chemical composition and microstructure, FeNb 65/60/55/50 offers reliable performance in demanding industries worldwide.

(FeNb 65/60/55/50 ferro niobium powder lump for welding rods wires and steel with factory )

FAQs of FeNb 65/60/55/50 ferro niobium powder lump for welding rods wires and steel with factory

Inquiry us