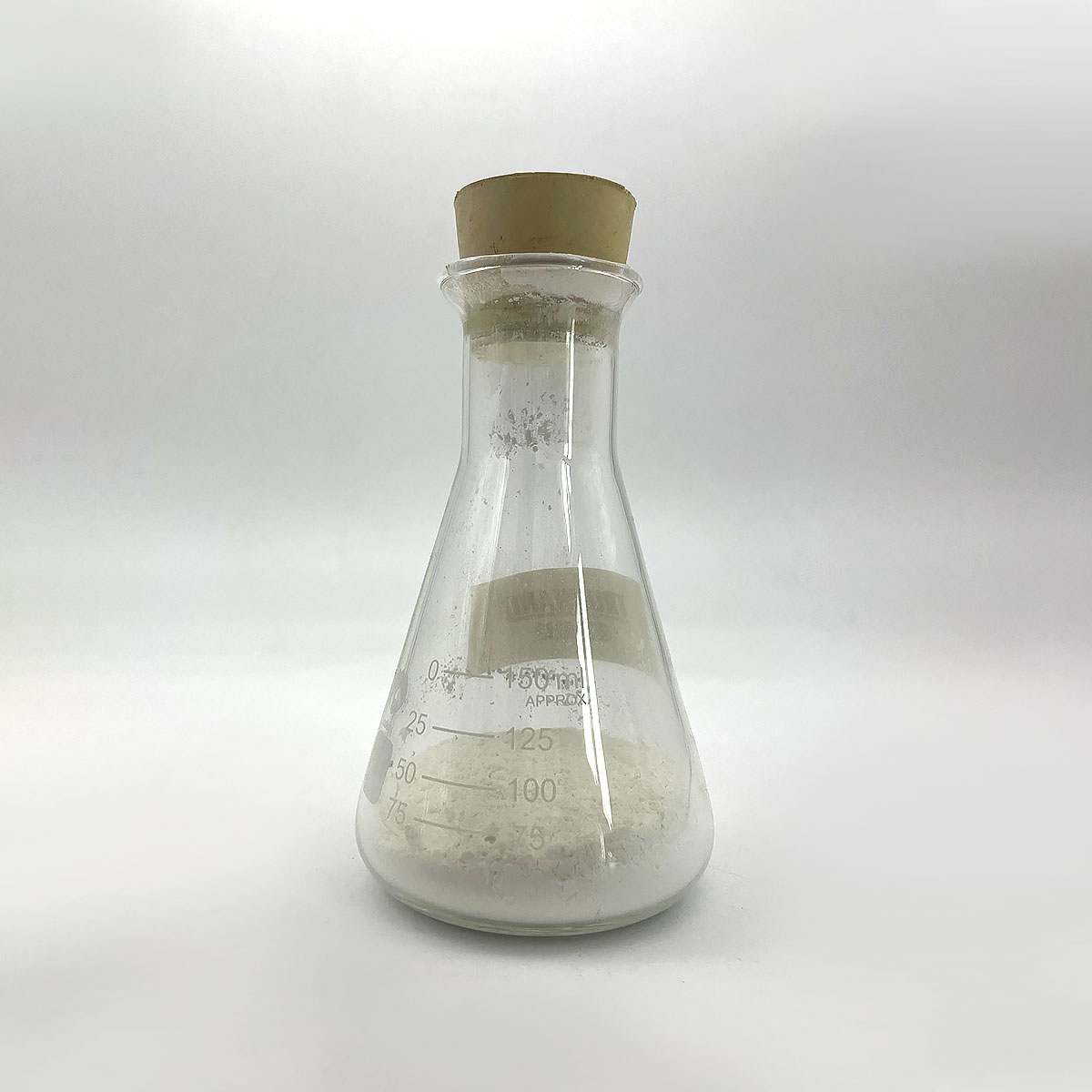

Overview of Niobium Zirconium alloy Customized pure Zirconium niobium cube tube per kg NbZr alloy ingots

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Niobium Zirconium alloy Customized pure Zirconium niobium cube tube per kg NbZr alloy ingots

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Niobium Zirconium alloy Customized pure Zirconium niobium cube tube per kg NbZr alloy ingots)

Parameters of Niobium Zirconium alloy Customized pure Zirconium niobium cube tube per kg NbZr alloy ingots

Niobium-Zirconium (NbZr) alloys, also known as Nb-Zr or Zircaloy, are a class of high-performance metallic materials that have gained significant recognition due to their exceptional properties, particularly in the nuclear and aerospace industries. These alloys are characterized by their low neutron absorption cross-section, high thermal conductivity, and excellent mechanical strength, making them ideal for applications where radiation resistance and corrosion tolerance are paramount.

Customizing pure Zirconium (Zr) and Niobium (Nb) cubes and tubes is a specialized process that caters to the specific requirements of various industries. The manufacturing of such products begins with the selection of high-quality elemental Zirconium and Niobium, which are then carefully combined to create the desired NbZr alloy composition. The purity of both elements plays a crucial role in determining the alloy’s performance, with higher purity levels generally resulting in improved properties.

The customization process involves melting and casting the Nb and Zr metals into ingots, which are then shaped and formed into cubes or tubes. This can be done using techniques like hot or cold working, extrusion, or forging, depending on the desired geometry and dimensions. The ingots are often subjected to heat treatment, such as annealing, to optimize the microstructure and enhance mechanical properties like strength, ductility, and toughness.

When it comes to the per-kg parameters of the NbZr alloy ingots, these can vary significantly based on the intended application. Key characteristics may include:

1. Density: Depending on the alloy composition, the density can range from around 6.5 g/cm³ for pure Zirconium to a slightly higher value for Nb-dominant alloys, typically around 6.7 g/cm³.

2. Melting Point: NbZr alloys generally have a higher melting point than pure Zirconium, with values ranging from 1390°C to 1550°C, allowing for efficient processing in high-temperature environments.

3. Thermal Conductivity: NbZr alloys are known for their excellent thermal conductivity, which helps dissipate heat effectively. This property is essential for applications like heat exchangers and nuclear reactors.

4. Strength: The mechanical strength of the alloy depends on the Nb content; Nb-rich alloys tend to have higher strength but lower ductility, while Zr-rich alloys offer better ductility at the expense of strength.

5. Creep Resistance: NbZr alloys exhibit excellent creep resistance, meaning they can maintain their structural integrity under prolonged exposure to high temperatures without significant deformation.

6. Corrosion Resistance: Both Niobium and Zirconium are inherently resistant to corrosion, but the alloy’s composition can further enhance this property, making it suitable for harsh environments.

7. Neutron Absorption: The low neutron absorption rate of NbZr alloys makes them suitable for use in nuclear reactors, where they serve as structural components.

In conclusion, customized pure Zirconium and Niobium cubes and tubes in NbZr alloy form are tailor-made to meet the unique demands of various industries. The precise composition, processing, and properties of these ingots are determined by factors such as the desired strength, thermal conductivity, and radiation resistance. With their exceptional performance characteristics, NbZr alloys continue to play a vital role in critical applications where reliability and safety are paramount.

(Niobium Zirconium alloy Customized pure Zirconium niobium cube tube per kg NbZr alloy ingots)

FAQs of Niobium Zirconium alloy Customized pure Zirconium niobium cube tube per kg NbZr alloy ingots

Inquiry us