Overview of Different grade of tantalum powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Different grade of tantalum powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

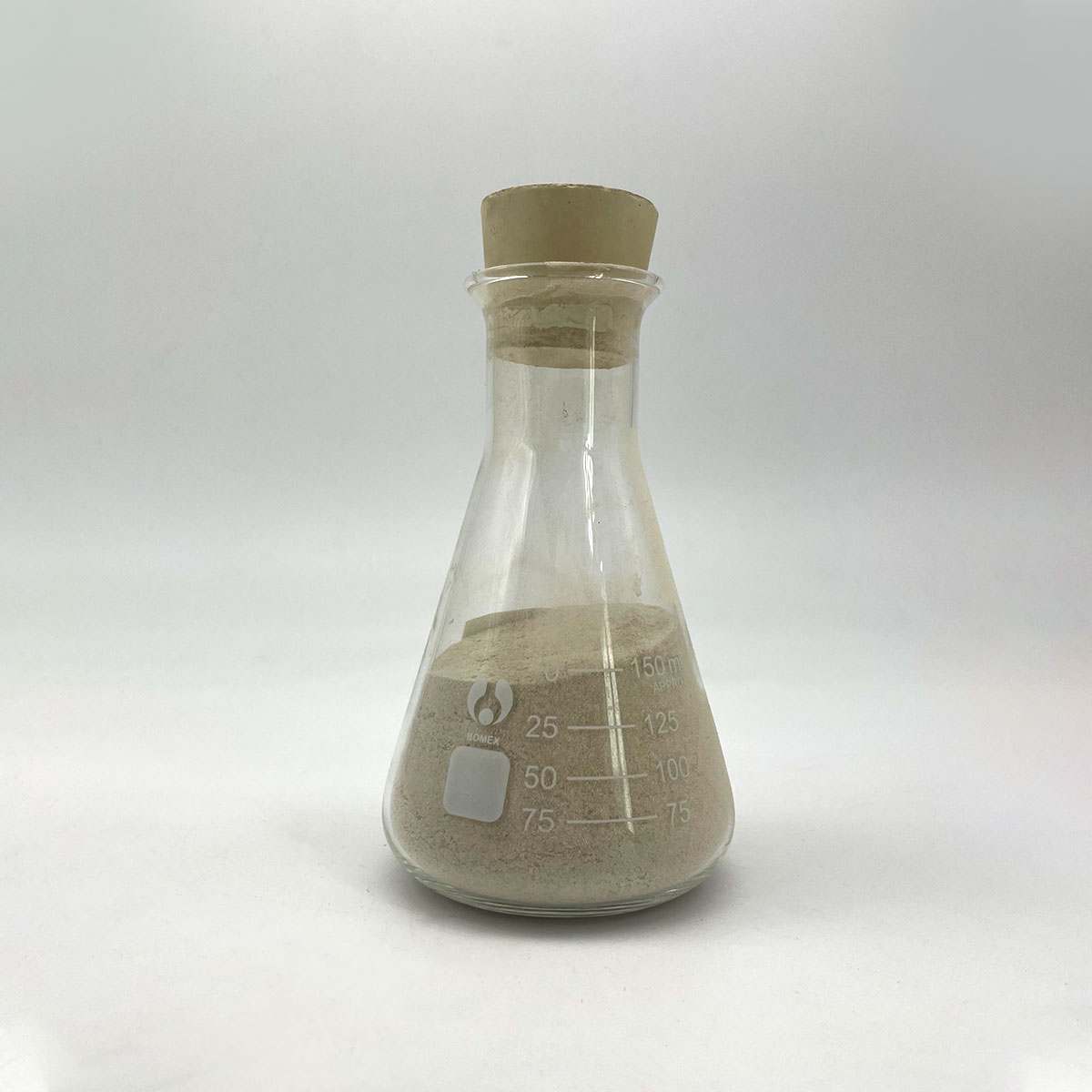

(Different grade of tantalum powder)

Parameters of Different grade of tantalum powder

Tantalum is a rare, lustrous transition metal with the atomic number 73, known for its exceptional strength, corrosion resistance, and high melting point. It is often referred to as “the niobium cousin” due to its similar chemical properties but with enhanced performance characteristics. Tantalum powders, which are produced through various processes like mechanical milling, electrolysis, or reduction, are available in different grades depending on their purity, particle size distribution, and intended application.

1. Purity: The purity of tantalum powder is a critical factor, typically measured as tantalum content by weight (Ta wt%). High-purity tantalum powders, such as 99.95% Ta or 99.99% Ta, are suitable for applications requiring minimal impurities, like chemical processing, semiconductor fabrication, and precision engineering. Lower purity grades, like 99.5% Ta or 99% Ta, are more affordable and find use in less demanding applications.

2. Particle Size Distribution: Tantalum powders are classified based on their particle size, which is crucial for controlling flowability, reactivity, and the final product’s properties. Common size ranges include sub-micron (<1 micron), micron (1-100 microns), and sub-millimeter (0.1-1 mm). Finer particles offer better surface area and reactivity, while coarser ones provide better handling and packing density. 3. Shape and Structure: Powders can be spherical, irregular, or have a specific shape, like flake or platelet structures. Spherical tantalum powder provides better flow properties, while flake or platelet shapes may enhance bonding in certain applications. The structure can also impact the mechanical properties of the final material when pressed or sintered. 4. Surface Finish: The surface finish of tantalum powder can range from smooth to rough, depending on the manufacturing process. A smoother surface promotes better adhesion during compaction or coating, while a rougher surface may be beneficial for increased frictional properties. 5. Thermal Conductivity: Tantalum is an excellent thermal conductor, and the grade can affect this property. Higher purity powders generally exhibit better thermal conductivity, making them suitable for applications where heat dissipation is crucial. 6. Mechanical Strength: The mechanical strength of tantalum powders can vary depending on the particle size and processing methods. Finer particles may have lower strength due to higher surface area and porosity, while larger particles result in higher strength and denser structures. 7. Cost and Availability: The cost of tantalum powder varies based on purity, supply, and demand. Higher purity grades are naturally more expensive, while lower grades offer a more affordable alternative. The availability of tantalum can be affected by geopolitical factors and global market fluctuations. In conclusion, tantalum powders come in various grades to cater to diverse industries and applications. Understanding the specific parameters, such as purity, particle size, and shape, is essential for selecting the right grade that optimizes performance, cost, and processability for each use case. As a versatile material, tantalum powder finds applications ranging from aerospace components to medical implants, demonstrating the importance of choosing the appropriate grade for the job at hand.

(Different grade of tantalum powder)

FAQs of Different grade of tantalum powder

Inquiry us