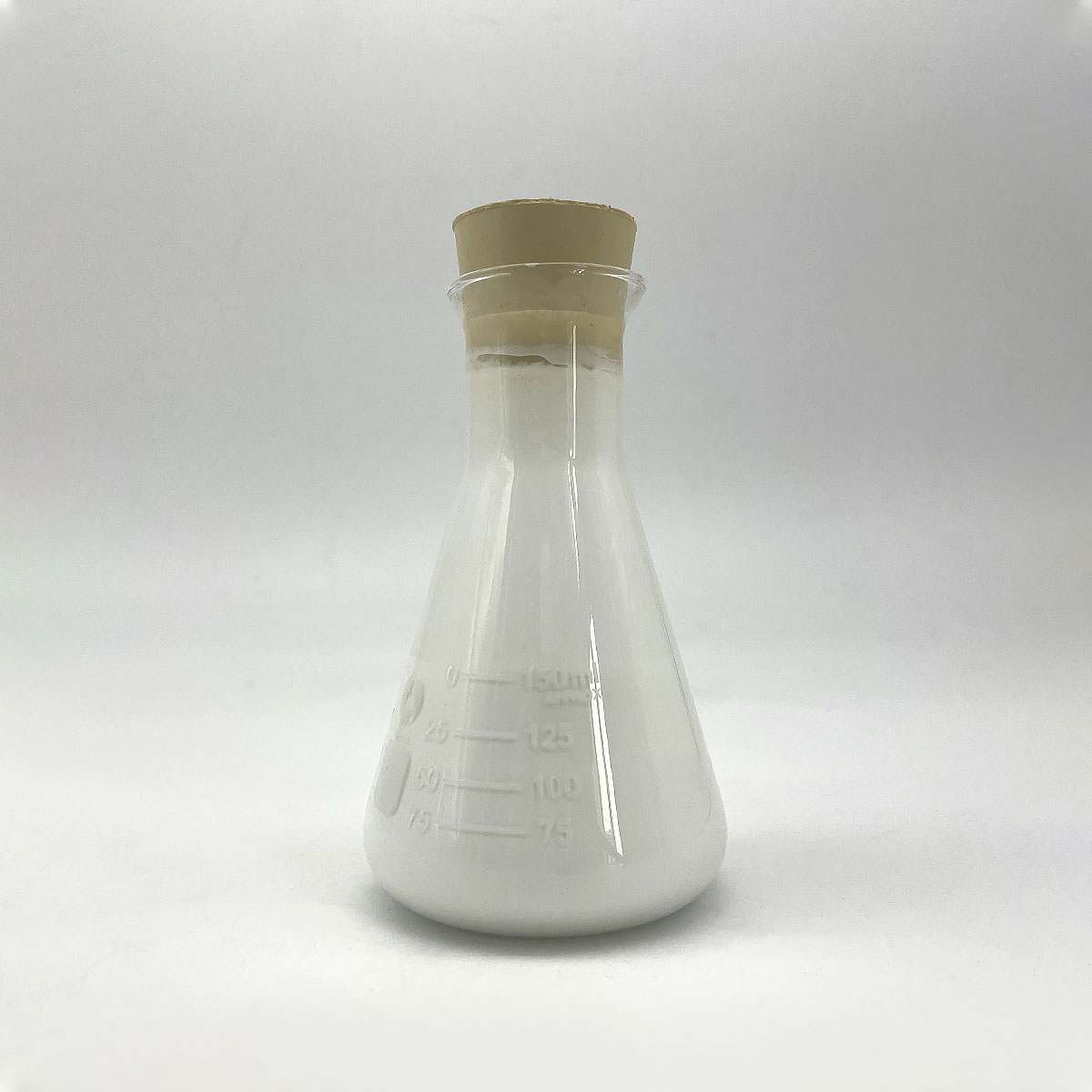

Overview of Mutiple Carbide Solution Powder 90Ta10Nb 90/10 Tantalum Carbide/Niobium Carbide

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Mutiple Carbide Solution Powder 90Ta10Nb 90/10 Tantalum Carbide/Niobium Carbide

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Mutiple Carbide Solution Powder 90Ta10Nb 90/10 Tantalum Carbide/Niobium Carbide)

Parameters of Mutiple Carbide Solution Powder 90Ta10Nb 90/10 Tantalum Carbide/Niobium Carbide

Multiple Carbide Solution Powder, specifically composed of a 90:10 ratio of Tantalum Carbide (TaC) to Niobium Carbide (NbC), is a high-performance material with exceptional properties that make it a popular choice in various industrial applications. This unique blend combines the strengths of both tantalum and niobium carbides, offering a versatile combination of hardness, wear resistance, and thermal stability.

Tantalum, known for its high melting point (3287°C or 5931°F), contributes to the powder’s exceptional heat resistance and durability. It is also corrosion-resistant, making it suitable for use in harsh environments where chemical attack is a concern. Tantalum carbide particles possess a low coefficient of friction, which is crucial for minimizing frictional losses in machinery and improving the efficiency of mechanical components.

Niobium, on the other hand, enhances the mechanical strength and toughness of the mixture. With a melting point of around 3260°C (5880°F), NbC offers improved wear resistance compared to pure tantalum carbide. Its presence also helps to refine the grain structure, leading to better surface finish and reduced microcracking, which is essential for maintaining the integrity of components under high stress.

The 90/10 ratio of TaC to NbC ensures a balance between these properties, allowing for an optimal performance in various engineering applications. The multiple carbide solution powder is often used in the manufacturing of cutting tools, wear-resistant coatings, bearings, and aerospace components due to its superior hardness and resistance to abrasive wear. It can also be employed in the production of electrical contacts, where high electrical conductivity and low contact resistance are critical.

Processing this powder involves advanced techniques like mechanical milling, sintering, or spark plasma sintering, which enable the formation of a homogeneous mixture with fine particle size distribution. This fine grain structure not only improves the overall mechanical properties but also enhances the material’s ability to bond during the manufacturing process.

In conclusion, the 90Ta10Nb multiple carbide solution powder is a valuable material in modern industry, characterized by its exceptional combination of strength, hardness, wear resistance, and thermal stability. Its tailored composition allows for efficient application in demanding environments and diverse industries, from automotive to electronics and aerospace. As technology continues to advance, the potential for further optimization and innovation with this material remains strong.

(Mutiple Carbide Solution Powder 90Ta10Nb 90/10 Tantalum Carbide/Niobium Carbide)

FAQs of Mutiple Carbide Solution Powder 90Ta10Nb 90/10 Tantalum Carbide/Niobium Carbide

Inquiry us