Overview of 99.9% metals basis Ta Tantalum Metal Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of 99.9% metals basis Ta Tantalum Metal Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

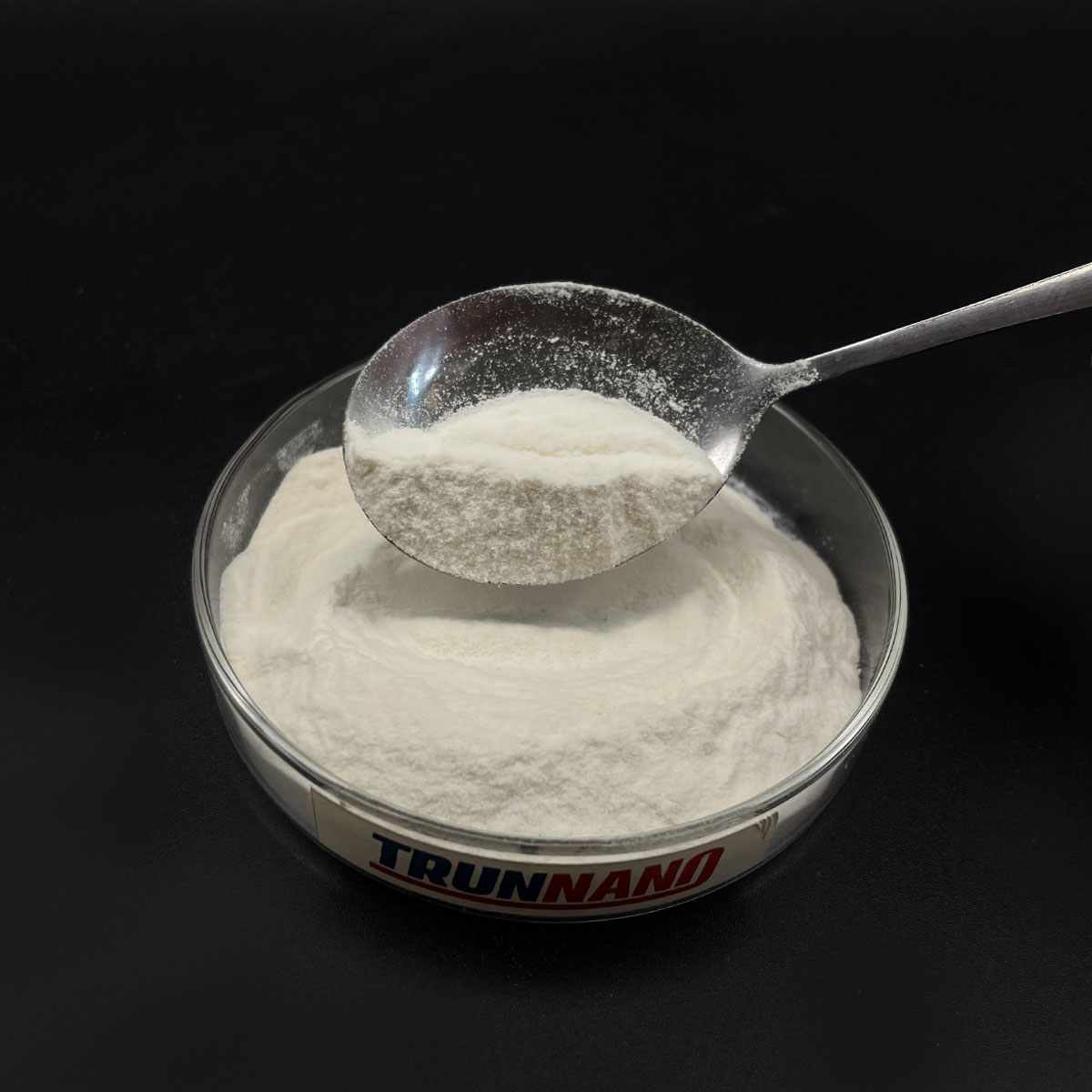

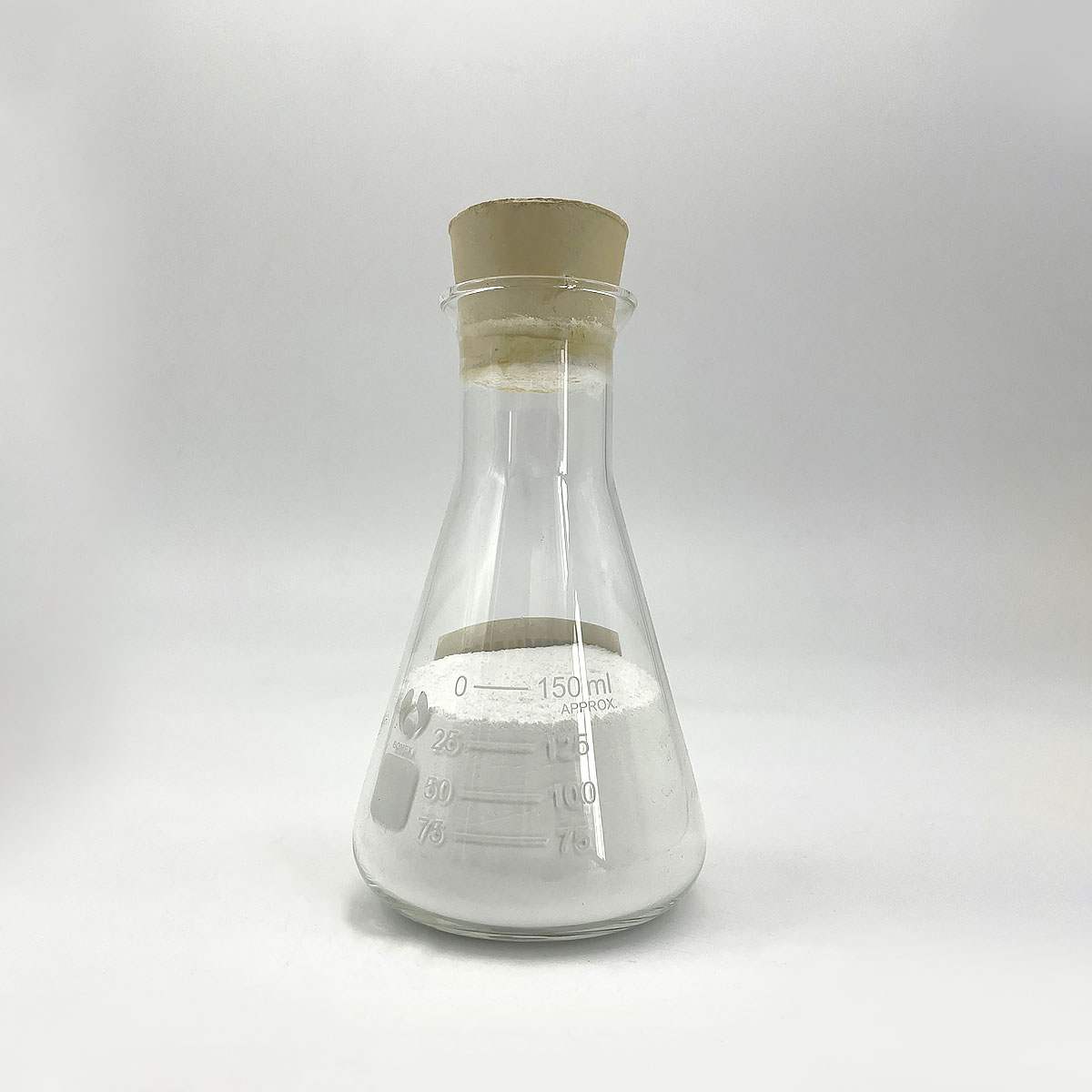

(99.9% metals basis Ta Tantalum Metal Powder)

Parameters of 99.9% metals basis Ta Tantalum Metal Powder

Tantalum, scientifically known as tantalum (Ta), is a rare and incredibly versatile metal that holds a significant position in various industrial applications due to its unique properties. Found naturally in the form of minerals like columbite and tantalite, tantalum is extracted through a complex refining process, which typically involves concentrating the ore, roasting, and hydrometallurgical or pyrometallurgical processes.

At 99.9% purity, this tantalum metal powder is considered to be extremely high-grade, ensuring a minimum impurity content and exceptional performance characteristics. The purity level is crucial for applications where precision, durability, and corrosion resistance are paramount. Tantalum’s near-ideal purity makes it ideal for use in demanding environments, such as aerospace, electronics, and chemical processing industries.

One of tantalum’s most notable features is its remarkable strength-to-weight ratio, making it an ideal material for lightweight yet strong components. This property is particularly useful in the aerospace industry, where weight reduction significantly impacts fuel efficiency and overall performance. Tantalum is used in jet engine components, missile parts, and satellite structures.

In the electronics sector, tantalum capacitors, often referred to as tantalums or tantalums, are renowned for their stability and long-term reliability. These capacitors can withstand extreme temperatures, vibrations, and aging, making them indispensable in high-frequency circuits, power supplies, and military equipment.

The high melting point of tantalum (3027°C) allows it to maintain its integrity under intense heat, which is why it finds application in heat exchangers, furnace linings, and other high-temperature applications. It also resists corrosion from acids, alkalis, and even molten salts, making it an ideal choice for chemical processing equipment.

Tantalum’s excellent wear resistance and lubricity make it suitable for bearings, bushings, and other components in machinery and automotive industries. Its non-magnetic nature further adds to its utility in magnetic shielding and precision instruments.

Another key aspect of tantalum metal powder is its ability to form a dense, adherent oxide layer upon exposure to air. This self-lubricating surface film, known as tantalum pentoxide, acts as a natural protection against corrosion and wear, extending the life of components in harsh environments.

In summary, the 99.9% metals basis tantalum metal powder is a highly sought-after material due to its exceptional properties like strength, durability, corrosion resistance, and thermal stability. Its widespread applications in aerospace, electronics, chemical processing, and mechanical industries highlight the versatility and importance of this precious metal in modern technology. The absence of any specific formatting in this description emphasizes its inherent qualities without needing to rely on a predefined structure.

(99.9% metals basis Ta Tantalum Metal Powder)

FAQs of 99.9% metals basis Ta Tantalum Metal Powder

Inquiry us