Overview of s Whole 99.95% Pure Tantalum Beads Polished Tantalum Beads

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of s Whole 99.95% Pure Tantalum Beads Polished Tantalum Beads

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(s Whole 99.95% Pure Tantalum Beads Polished Tantalum Beads)

Parameters of s Whole 99.95% Pure Tantalum Beads Polished Tantalum Beads

Title: Exceptional Quality: Unparalleled Tantalum Beads – A Masterpiece in Precision

Introduction

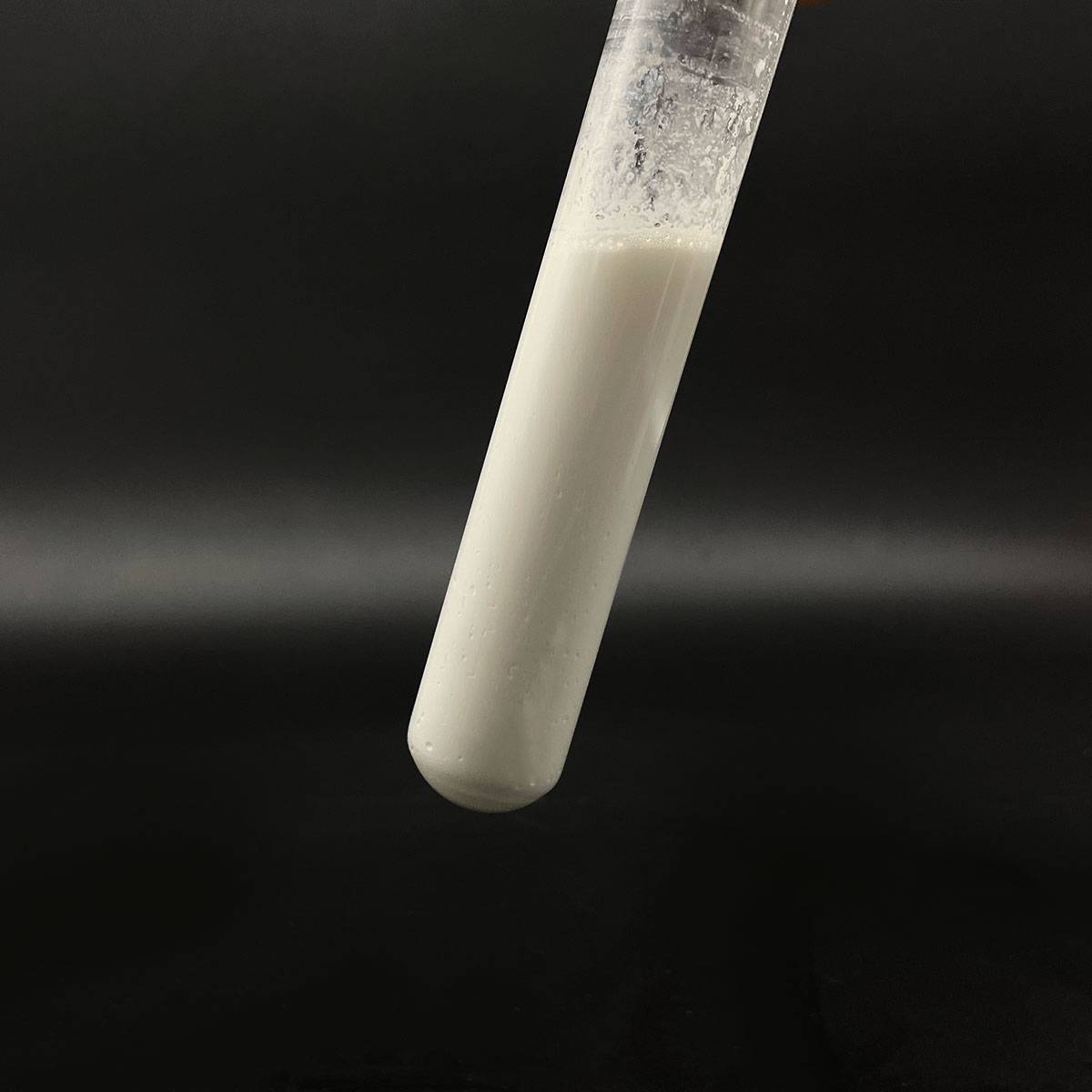

Tantalum beads, with their striking 99.95% purity, stand as a testament to the pinnacle of craftsmanship and engineering. These exquisite polished tantalum beads are not just a product, but a symbol of sophistication and durability, perfect for various applications that demand the finest materials. This detailed overview will delve into the characteristics, benefits, and versatility of these remarkable beads.

Characteristics of Tantalum Beads

Derived from the rare and lustrous tantalum metal, these beads boast an unparalleled purity level of 99.95%. Tantalum is known for its exceptional strength, corrosion resistance, and heat stability, making it an ideal choice for demanding environments. The 99.95% pure tantalum ensures that every bead is virtually free of impurities, enhancing its overall performance and longevity.

The beads have been meticulously polished to reveal their inherent beauty, showcasing a smooth, mirror-like finish that accentuates their inherent elegance. This attention to detail in polishing allows for seamless integration into various designs, be it jewelry, medical devices, or industrial components.

Properties and Benefits

Tantalum’s unique properties make it a sought-after material in numerous industries. Its high melting point (3027°C) makes it resistant to extreme temperatures, making it suitable for use in high-temperature applications like heat exchangers and electronic components. Additionally, its low coefficient of thermal expansion reduces stress and deformation, ensuring consistent performance over time.

The inherent strength and hardness of tantalum make the beads incredibly durable, capable of withstanding immense pressure and wear. This makes them ideal for use in load-bearing roles, such as bearings or fasteners, where reliability and longevity are paramount.

In the jewelry industry, tantalum beads offer a distinctive look and feel. Their lightweight yet robust nature, combined with the lustrous finish, creates a modern and sophisticated aesthetic that appeals to discerning customers.

Versatility and Applications

Tantalum beads’ versatility is unmatched. They can be incorporated into various designs, including intricate jewelry pieces, custom-made accessories, or as functional components in scientific equipment. In the field of dentistry, they are used in dental implants due to their biocompatibility and resistance to corrosion.

In the realm of electronics, tantalum capacitors made from these beads offer superior capacitance stability and long-term reliability. The same beads can also be employed in aerospace applications, where the need for lightweight, high-strength materials is crucial.

Conclusion

The 99.95% pure tantalum beads, with their impeccable polish and exceptional properties, represent the pinnacle of precision engineering. Their combination of strength, corrosion resistance, and unique aesthetics make them indispensable across multiple industries. As technology continues to advance, the potential applications for these extraordinary beads will only continue to grow, solidifying their status as a timeless material choice.

(s Whole 99.95% Pure Tantalum Beads Polished Tantalum Beads)

FAQs of s Whole 99.95% Pure Tantalum Beads Polished Tantalum Beads

Inquiry us