Overview of 99.99% In2Se3 Powder Indium Selenide

Telluride and selenide compounds play a significant role in the field of semiconductors, particularly in the development of advanced electronic and optoelectronic devices. These materials belong to the chalcogenide family, characterized by their ability to form compounds with elements from groups IV-VI in the periodic table.

Tellurides: Compounds containing tellurium (Te) as the chalcogen. Examples include cadmium telluride (CdTe), mercury telluride (HgTe), and zinc telluride (ZnTe). These materials have found applications in solar cells, infrared detectors, and high-speed electronics due to their tunable bandgap, high electron mobility, and good thermal stability.

Selenides: Similar to tellurides, but with selenium (Se) replacing tellurium. Notable examples are cadmium selenide (CdSe), gallium selenide (GaSe), and zinc selenide (ZnSe). Selenide compounds are widely used in light-emitting diodes (LEDs), laser diodes, and solar cells due to their direct bandgap properties and efficient light absorption/emission capabilities.

Feature of 99.99% In2Se3 Powder Indium Selenide

Direct Bandgap: Many telluride and selenide semiconductors have direct bandgaps, which facilitate efficient light emission and absorption processes. This makes them suitable for optoelectronic applications such as LEDs and lasers.

Tunable Bandgap: The bandgap of these materials can be adjusted by alloying or altering the composition (e.g., CdSe to CdTe), enabling customization for specific device requirements across a wide spectrum of wavelengths.

High Electron Mobility: Materials like HgCdTe exhibit high electron mobility, which is crucial for high-speed electronic devices and low-noise detector applications.

Thermal Stability: Some tellurides and selenides, like ZnTe and ZnSe, demonstrate good thermal stability, making them suitable for high-temperature operation and processing.

Non-Toxic Alternatives: With increasing environmental concerns, there’s a push towards exploring less toxic alternatives to commonly used semiconductors. For instance, Cd-based tellurides and selenides are being replaced or combined with less toxic elements like Mg or Mn in some applications.

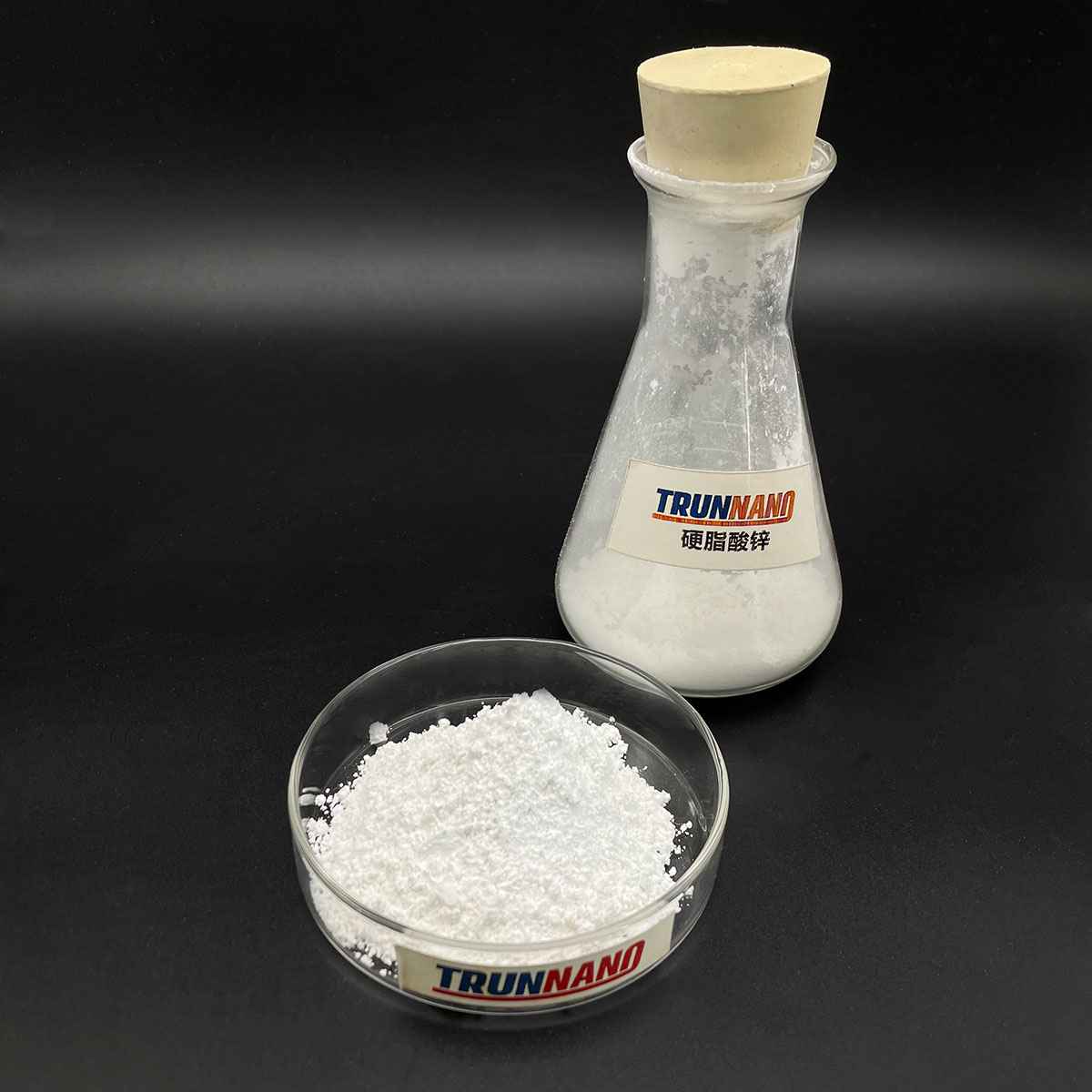

(99.99% In2Se3 Powder Indium Selenide)

Parameters of 99.99% In2Se3 Powder Indium Selenide

Indium selenide (In2Se3), a binary compound of indium and selenium, is an intriguing material with unique properties that have attracted significant attention in various fields, including optoelectronics, thin-film solar cells, and spintronics. As a 99.99% pure powder form, it boasts exceptional purity, ensuring high-performance applications.

The chemical formula In2Se3 signifies that each molecule consists of two indium atoms (In) chemically bonded to three selenium atoms (Se). The crystal structure of In2Se3 is typically rhombohedral, adopting a layered configuration where indium and selenium atoms alternate in a hexagonal arrangement. This arrangement gives rise to its characteristic metallic luster and distinct electronic properties.

One of the key attributes of In2Se3 is its direct bandgap, which makes it an excellent candidate for optoelectronic devices. At room temperature, the bandgap lies around 1.5 to 1.7 electron volts (eV), enabling efficient absorption and conversion of light into electrical energy. This property is particularly useful in photovoltaic applications, where it can enhance the efficiency of solar cells by capturing a broader range of the solar spectrum.

In addition to its potential in solar technology, In2Se3 has shown promise in spintronics due to its intrinsic magnetic properties. Some studies suggest that it can exhibit ferromagnetism or even ferrimagnetism under certain conditions, making it a possible material for spintronic devices that utilize the spin of electrons for data storage and processing.

The high purity of the 99.99% In2Se3 powder ensures minimal impurities, which is crucial for maintaining its optimal performance. Impurities can introduce defects or degrade the desired properties, so this level of purity is essential for achieving reliable device performance and longevity.

Processing In2Se3 powder into thin films or nanostructures requires specialized techniques such as molecular beam epitaxy (MBE) or chemical vapor deposition (CVD). These methods allow for precise control over film thickness and uniformity, crucial for obtaining consistent and high-quality devices.

Furthermore, In2Se3’s thermal stability is another advantage. It has a relatively high melting point, around 856°C, which allows it to withstand high temperatures during fabrication without undergoing significant degradation. This thermal robustness is vital in applications like thermoelectric generators, where materials need to maintain their functionality under elevated temperatures.

Lastly, environmental concerns surrounding indium usage have led to research on recycling and sustainable sourcing. In2Se3’s compositional simplicity, with both indium and selenium being abundant elements, makes it a potentially attractive material for recycling efforts, reducing the overall environmental footprint.

In summary, 99.99% pure In2Se3 powder offers a promising platform for advanced technological applications due to its direct bandgap, magnetic properties, and high purity. Its suitability in optoelectronics, spintronics, and potential for sustainability make it a material of interest in the rapidly evolving field of materials science. Further research and development will continue to unlock its full potential and drive innovation in these sectors.

(99.99% In2Se3 Powder Indium Selenide)

FAQ of Semiconductor Materials

Inquiry us