Overview of factory 4N, 5N High Purity Bismuth Telluride Powder Bi2Te3 1304-82-1 supttering target baoji tianbo metal

Telluride and selenide compounds play a significant role in the field of semiconductors, particularly in the development of advanced electronic and optoelectronic devices. These materials belong to the chalcogenide family, characterized by their ability to form compounds with elements from groups IV-VI in the periodic table.

Tellurides: Compounds containing tellurium (Te) as the chalcogen. Examples include cadmium telluride (CdTe), mercury telluride (HgTe), and zinc telluride (ZnTe). These materials have found applications in solar cells, infrared detectors, and high-speed electronics due to their tunable bandgap, high electron mobility, and good thermal stability.

Selenides: Similar to tellurides, but with selenium (Se) replacing tellurium. Notable examples are cadmium selenide (CdSe), gallium selenide (GaSe), and zinc selenide (ZnSe). Selenide compounds are widely used in light-emitting diodes (LEDs), laser diodes, and solar cells due to their direct bandgap properties and efficient light absorption/emission capabilities.

Feature of factory 4N, 5N High Purity Bismuth Telluride Powder Bi2Te3 1304-82-1 supttering target baoji tianbo metal

Direct Bandgap: Many telluride and selenide semiconductors have direct bandgaps, which facilitate efficient light emission and absorption processes. This makes them suitable for optoelectronic applications such as LEDs and lasers.

Tunable Bandgap: The bandgap of these materials can be adjusted by alloying or altering the composition (e.g., CdSe to CdTe), enabling customization for specific device requirements across a wide spectrum of wavelengths.

High Electron Mobility: Materials like HgCdTe exhibit high electron mobility, which is crucial for high-speed electronic devices and low-noise detector applications.

Thermal Stability: Some tellurides and selenides, like ZnTe and ZnSe, demonstrate good thermal stability, making them suitable for high-temperature operation and processing.

Non-Toxic Alternatives: With increasing environmental concerns, there’s a push towards exploring less toxic alternatives to commonly used semiconductors. For instance, Cd-based tellurides and selenides are being replaced or combined with less toxic elements like Mg or Mn in some applications.

( factory 4N, 5N High Purity Bismuth Telluride Powder Bi2Te3 1304-82-1 supttering target baoji tianbo metal )

Parameters of factory 4N, 5N High Purity Bismuth Telluride Powder Bi2Te3 1304-82-1 supttering target baoji tianbo metal

Factory 4N and 5N High Purity Bismuth Telluride (Bi2Te3) Powders: A Comprehensive Overview

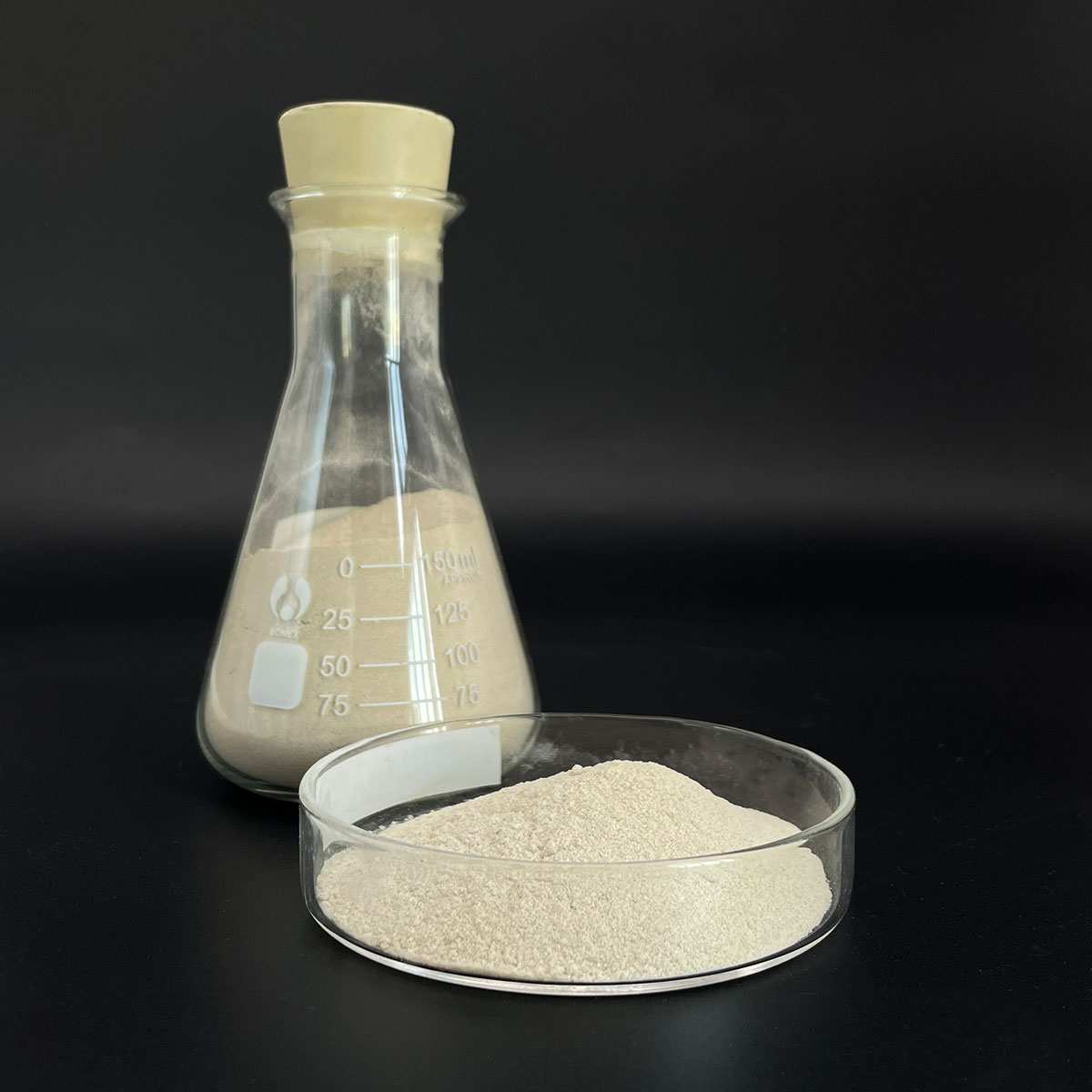

Bismuth Telluride (Bi2Te3), also known as Bi-Te or BTO, is a fascinating material with exceptional properties that make it a sought-after component in various scientific and industrial applications, particularly in optoelectronics, thermoelectrics, and superconductors. Factory 4N and 5N high purity Bi2Te3 powders are the premium grade products offered by Baoji Tianbo Metal, a leading manufacturer in this field.

4N and 5N refer to the standard notation for denoting the level of purity in metals and compounds. The ‘N’ stands for ‘nines,’ where ‘4N’ indicates 99.99% purity and ‘5N’ signifies an even higher purity level, typically around 99.9999%. This high purity is crucial for ensuring minimal impurities and consistent performance in the final application.

Bismuth Telluride powders are synthesized through a meticulous process that starts with the selection of high-quality raw materials, which include elemental bismuth and tellurium. The purification process begins with refining, followed by grinding and milling to achieve the desired particle size and morphology. To attain 4N and 5N grades, stringent purification techniques such as sublimation, zone refining, or chemical leaching may be employed.

In the form of a sputtering target, Bi2Te3 powder finds its application in thin film deposition processes. Sputtering is a technique used to deposit thin layers of materials onto substrates by bombarding them with energetic ions. The high purity of these powders ensures that the deposited films have fewer defects and better crystal structure, resulting in enhanced device performance.

Baoji Tianbo Metal, located in Baoji, Shaanxi, China, is known for its expertise in producing these high-purity Bi2Te3 powders. The company invests in advanced equipment and adheres to strict quality control measures to maintain product consistency. Their commitment to research and development enables them to continuously improve their manufacturing processes, ensuring customers receive the best possible materials.

The applications of Bi2Te3 powders are diverse, ranging from photovoltaic cells to thermoelectric generators, where they exhibit efficient conversion of heat to electricity. In optoelectronics, Bi2Te3 is utilized for infrared detectors and solar cells due to its unique electronic band structure. As a superconductor, it has potential in high-speed electronics and quantum computing.

In conclusion, Factory 4N and 5N high purity Bismuth Telluride powders from Baoji Tianbo Metal are a testament to precision engineering and the pursuit of excellence in material science. These powders serve as critical components in various technological innovations, and their superior purity guarantees optimal performance in demanding applications. As research and development continue to push the boundaries of materials science, Bi2Te3 will undoubtedly remain at the forefront of these advancements.

( factory 4N, 5N High Purity Bismuth Telluride Powder Bi2Te3 1304-82-1 supttering target baoji tianbo metal )

FAQ of Semiconductor Materials

Inquiry us