Overview of Thermoelectric Materials CAS 1304-82-1 99.99% Bi2Te3 Powder Bismuth Telluride

Telluride and selenide compounds play a significant role in the field of semiconductors, particularly in the development of advanced electronic and optoelectronic devices. These materials belong to the chalcogenide family, characterized by their ability to form compounds with elements from groups IV-VI in the periodic table.

Tellurides: Compounds containing tellurium (Te) as the chalcogen. Examples include cadmium telluride (CdTe), mercury telluride (HgTe), and zinc telluride (ZnTe). These materials have found applications in solar cells, infrared detectors, and high-speed electronics due to their tunable bandgap, high electron mobility, and good thermal stability.

Selenides: Similar to tellurides, but with selenium (Se) replacing tellurium. Notable examples are cadmium selenide (CdSe), gallium selenide (GaSe), and zinc selenide (ZnSe). Selenide compounds are widely used in light-emitting diodes (LEDs), laser diodes, and solar cells due to their direct bandgap properties and efficient light absorption/emission capabilities.

Feature of Thermoelectric Materials CAS 1304-82-1 99.99% Bi2Te3 Powder Bismuth Telluride

Direct Bandgap: Many telluride and selenide semiconductors have direct bandgaps, which facilitate efficient light emission and absorption processes. This makes them suitable for optoelectronic applications such as LEDs and lasers.

Tunable Bandgap: The bandgap of these materials can be adjusted by alloying or altering the composition (e.g., CdSe to CdTe), enabling customization for specific device requirements across a wide spectrum of wavelengths.

High Electron Mobility: Materials like HgCdTe exhibit high electron mobility, which is crucial for high-speed electronic devices and low-noise detector applications.

Thermal Stability: Some tellurides and selenides, like ZnTe and ZnSe, demonstrate good thermal stability, making them suitable for high-temperature operation and processing.

Non-Toxic Alternatives: With increasing environmental concerns, there’s a push towards exploring less toxic alternatives to commonly used semiconductors. For instance, Cd-based tellurides and selenides are being replaced or combined with less toxic elements like Mg or Mn in some applications.

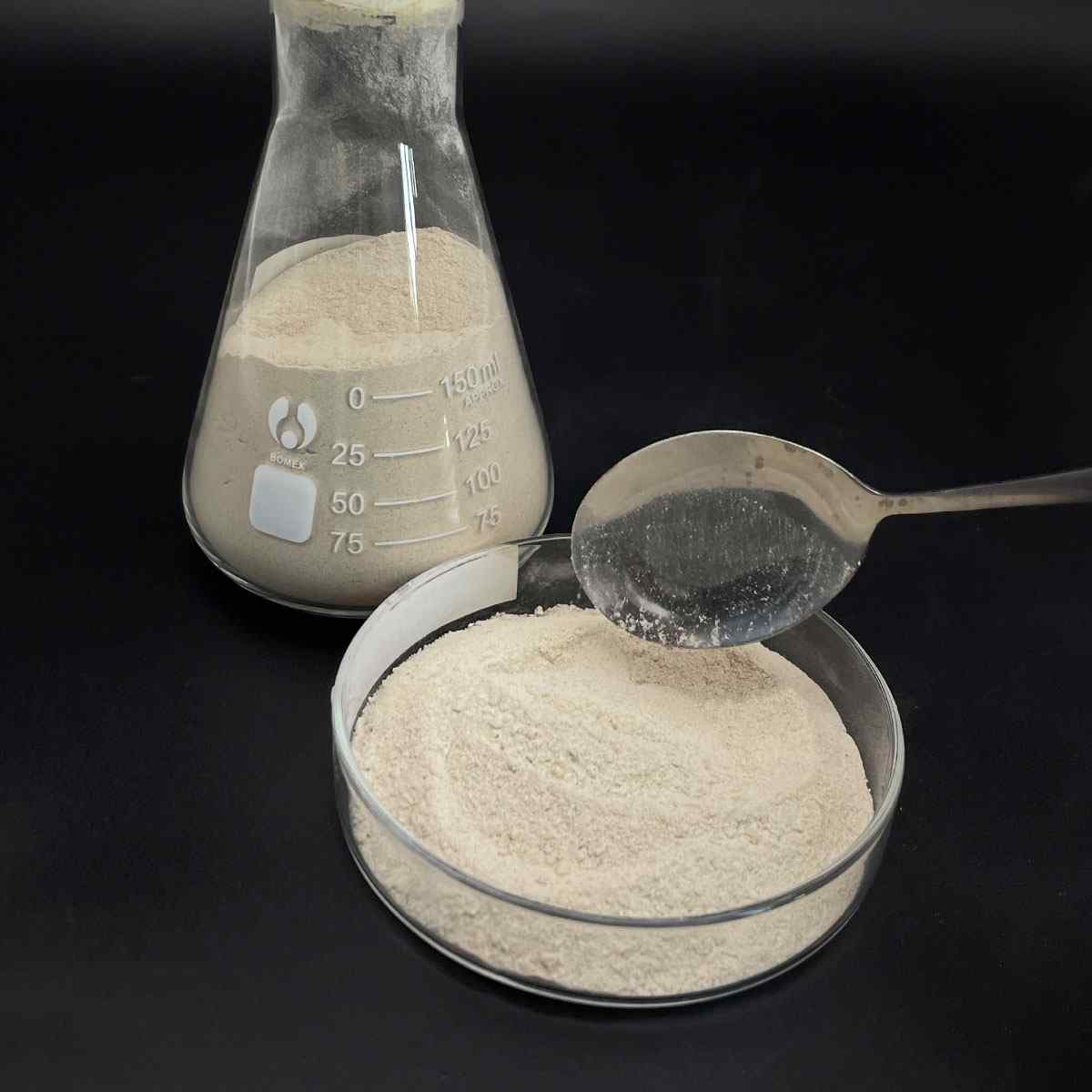

(Thermoelectric Materials CAS 1304-82-1 99.99% Bi2Te3 Powder Bismuth Telluride)

Parameters of Thermoelectric Materials CAS 1304-82-1 99.99% Bi2Te3 Powder Bismuth Telluride

Bismuth Telluride (Bi2Te3), also known as Tellurium-Bismuthide, is a fascinating thermoelectric material with the chemical formula Bi2Te3 and the CAS number 1304-82-1. This compound finds its significance in various scientific applications due to its unique properties that make it an excellent candidate for converting temperature differences into electrical energy, a phenomenon known as the Seebeck effect.

At 99.99% purity, Bi2Te3 powder is of exceptional quality and offers high efficiency in thermoelectric devices. The material consists of two bismuth atoms (Bi) covalently bonded with three tellurium atoms (Te), forming a rhombohedral crystal structure. This structure contributes to its intrinsic properties, such as a low thermal conductivity and a relatively high electrical conductivity, which are crucial for thermoelectric performance.

The key parameters that define Bi2Te3 include its Seebeck coefficient, electrical conductivity, and thermal conductivity. The Seebeck coefficient, or thermopower, measures the voltage generated per unit temperature difference across the material. A higher Seebeck coefficient indicates better thermoelectric efficiency. Bi2Te3 exhibits a moderate Seebeck coefficient, typically around 500 to 600 μV/K, making it suitable for various temperature ranges.

Electrical conductivity, on the other hand, refers to the ease with which electrons can flow through the material. Pure Bi2Te3 has a relatively high electrical conductivity, especially at room temperature, which aids in efficient heat-to-electricity conversion. However, this property can be manipulated by introducing nanostructuring or doping to optimize performance for specific applications.

Thermal conductivity is the measure of how well a material conducts heat. Low thermal conductivity is essential for thermoelectric materials to maximize the temperature gradient and improve the efficiency of power generation. Bi2Te3 has an intrinsically low lattice thermal conductivity, which contributes to its thermoelectric advantage. However, impurities or defects can inadvertently increase thermal conductivity, so maintaining high purity is crucial.

Bi2Te3’s thermoelectric properties make it useful in several applications, including waste heat recovery, refrigeration systems, and power generation from temperature gradients, such as in automobiles and industrial processes. It is also being explored in emerging technologies like wearable electronics and thermoelectric cooling devices.

Despite its advantages, Bi2Te3 faces challenges in large-scale commercialization due to its toxicity and environmental concerns. Researchers are continually working on developing safer alternatives or improving processing methods to minimize these drawbacks while preserving its exceptional thermoelectric performance.

In summary, Bi2Te3 (CAS 1304-82-1) with a 99.99% pure powder form is a highly sought-after thermoelectric material characterized by its moderate Seebeck coefficient, high electrical conductivity, and low thermal conductivity. These properties enable efficient energy conversion and make it a promising candidate for a wide range of applications, from waste heat management to advanced electronic devices. However, ongoing research focuses on overcoming limitations and enhancing its performance for widespread adoption in the future.

(Thermoelectric Materials CAS 1304-82-1 99.99% Bi2Te3 Powder Bismuth Telluride)

FAQ of Semiconductor Materials

Inquiry us